BMW Group starts second production line for battery module at Leipzig’s facility

BMW Group has announced the expansion of EV components production in its Leipzig plant in the German state of Saxony, with the inauguration of the second production line for battery modules.

The new assembly line manufactures battery modules for the BMW i4 fully-electric cars made in Munich. The plant's first production line went on stream in May 2021, and supplies the battery modules for the BMW iX model.

"Today's launch of Leipzig's second battery module production line makes an important contribution to delivering the battery components needed to make a growing number of electrified vehicles," said Markus Fallböhmer, Head of Engine and E-Drive Production at the BMW Group.

The gradual expansion of e-component production is taking the BMW Group ever closer to its goal for 2030, when fully electric models are expected to account for at least half of the BMW Group's sales, the company claims.

The new battery module production line comes at an investment of around €70 million. The production of high-voltage batteries involve two stages, namely, the module production and high-voltage battery assembly.

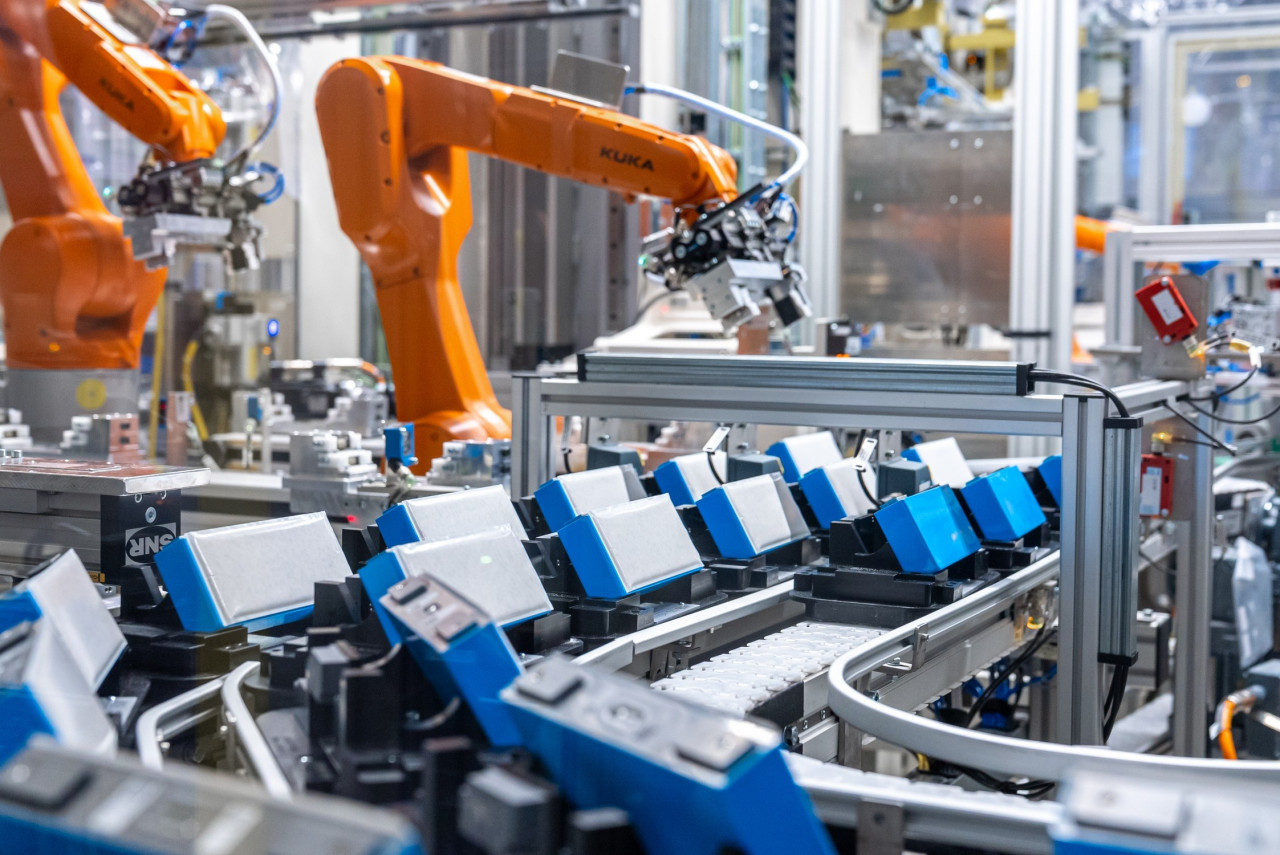

Module production is a highly automated process in which the lithium-ion cells first undergo plasma cleaning, before being coated by a specially developed system to ensure optimal insulation. They are then combined to form larger units known as modules. The BMW Group sources its battery cells from partners who produce them to the company's exact specifications.

The completed battery modules are then installed in an aluminum housing, together with the connectors and the control and cooling units. The size and shape of the housing and the number of battery modules used differ depending on the vehicle variant. So, each high-voltage battery can be optimally adjusted to suit the car it will power.

Each battery module passes through 196 production stations in total, before it is complete and ready for further processing, according to BMW Group.

The company has also revealed that the e-components production in Leipzig will become even more extensive and flexible as early as next year, including the making of MINI Countryman, due to roll off the assembly lines from 2023 with an all-electric drivetrain.

The high-voltage batteries and battery components for the full range BMW and MINI electric vehicles are made at Dingolfing, Leipzig and Regensburg facilities in Germany, as well as Spartanburg in USA and Shenyang in China. There is also localized production line of high-voltage batteries in Thailand.

In Munich, the BMW Group operates an e-drive pilot plant and a Battery Cell Competence Centre, where battery cell value-creation processes are analyzed, and technologies for production processes are refined.

A Cell Manufacturing Competence Centre in Parsdorf near Munich is also on the making. The new facility will be a pilot plant for battery cell production as well. It will model series production of lithium-ion battery cells and validate the feasibility of their large-scale manufacture, the company says.