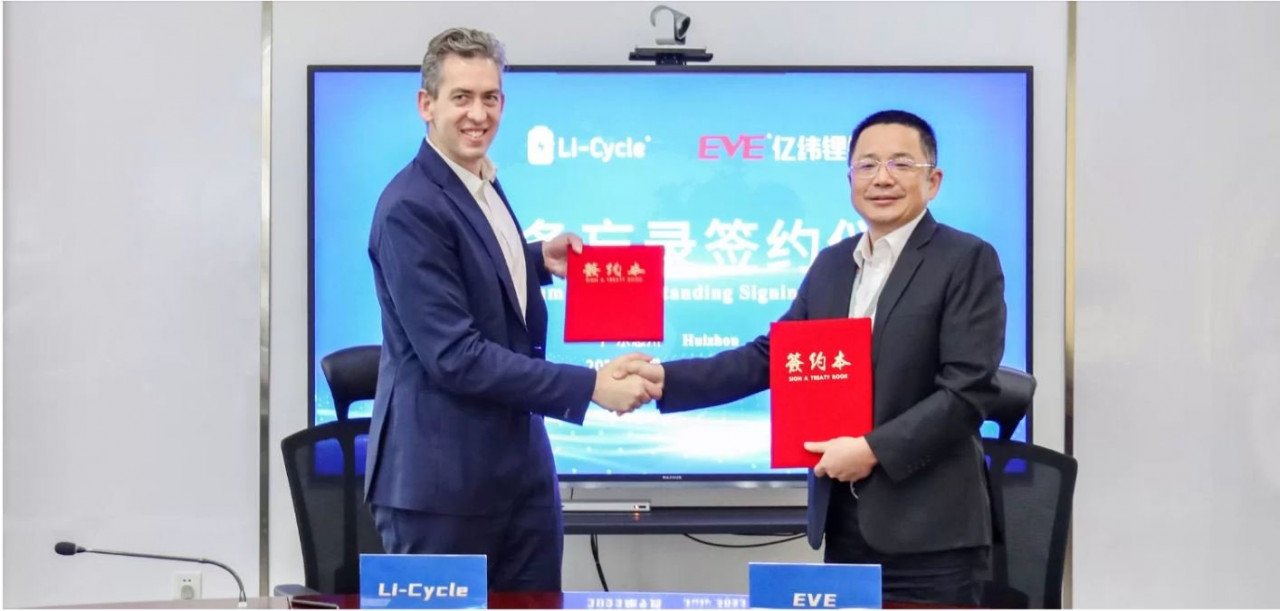

Closing the Loop: EVE Energy teams up with Li-Cycle for tackling battery waste

Leading lithium-ion battery cell manufacturer, EVE Energy Co. Ltd. (EVE or EVE Energy) has partnered with Li-Cycle Holdings Corp. (Li-Cycle) to tackle lithium-ion battery waste and explore high environmental standard lithium-ion battery recycling solutions for EVE's battery materials.

As part of the MoU signed on Tuesday (July 11), the partners will explore global sustainable recycling solutions for EVE lithium-ion battery materials in the North American market, as well as battery manufacturing scrap generated at EVE's planned lithium-ion battery cell manufacturing facilities in Malaysia and Hungary.

"We are excited to collaborate with EVE, a proven global leader in lithium-ion battery cell manufacturing, to provide a sustainable resource recovery solution for lithium-ion battery products and manufacturing scrap," said Tim Johnston, co-founder and Executive Chair of Li-Cycle.

Currently EVE is working on expanding its global presence, in addition to EVE's large lithium-ion battery manufacturing footprint in Asia, the company has announced plans to build its first European battery manufacturing facility in Hungary, and a lithium-ion battery cell manufacturing facility in Malaysia.

The collaboration is expected to support EVE's environmental goals through a closed-loop supply solution and build on its movement towards enabling electrification globally.

"We are pleased to partner with Li-Cycle to discuss the establishment of a high environmental standard battery recycling system to support sustainable development," said Mr. Jianhua Liu, co-founder and CEO of EVE Energy.

"To better serve our international customers, we are going to construct green battery factories in Europe and Southeast Asia…we are implementing strategic initiatives such as industry chain integration, team internationalization, and the application of international operational models," Liu added.