Epsilon Advanced Material has announced that it has received an initial order for its Anode precursor material from the top two anode makers in Japan & China. The company is targeting sales volumes of 10,000 Metric Tonnes of anode precursor material in FY22 with exports being a significant contributor to the sales. Epsilon is also in the advanced stages of getting its material qualified with upcoming cell manufacturing facilities in the US and Europe.

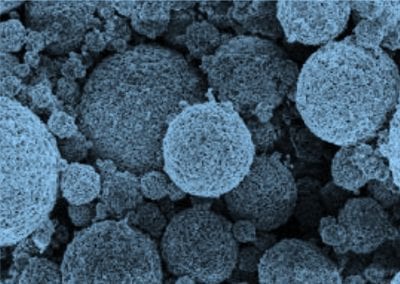

Globally Synthetic graphite has a 60 percent market share in the anode material space. With these positive results, Epsilon is successfully qualified as the supplier in the global Lithium-ion battery supply chain. This is in line with Epsilon Carbon’s broader strategy to become the world’s first vertically integrated and sustainable anode material producer in the Lithium-ion battery supply chain with a plan to expand synthetic graphite capacity to 35,000 MT by 2025.

According to Mr. Vikram Handa, Managing Director of Epsilon Carbon, “Technical performance anode makers has shown that Epsilon material is highly suited to support cell-makers in developing longer-range & quick-charging batteries. This has been also been appreciated by the Battery Electronic Vehicle (BEV) segment. Anode manufacturing is an essential part of the battery supply chain. Epsilon Carbon with our sustained backward integration of raw material is best placed to support increase this value addition for Indian-based Battery/Cell manufacturers while continuing to service our Global clients’ demand.”

With the growing acceptance of electric vehicles, the Li-ion battery is likely to dominate over the next decade. Globally, many countries have announced plans to set-up Battery making Giga factories to support their Mobility & Energy storage needs of 2600 GWh by 2030.

Under Aatmanirbhar Bharat initiatives government has come-up with a PLI scheme for 10 sectors including Advanced Cell Chemistry battery to facilitate & promote Indigenous supply chain manufacturing capabilities. Through this scheme at least, 5 Giga factories (10 GWh each) are expected to come-up immediately with each factory attracting an investment of $1 billion. Under this scheme, there is a total cash subsidy of INR ~34000 crores over the next 10 years.

Cell manufacturers looking forward to set-up their facility under the PLI scheme are approaching Epsilon to secure their raw material needs. Epsilon being a 100 percent indigenous producer of anode material, gives them a competitive advantage in complying with localization norms to avail subsidies. Epsilon’s manufacturing leadership in graphite anodes will make India self-sufficient as a key raw material for LiB cells. With a capacity of 35000 Tons of synthetic graphite, Epsilon would be able to support 35 GWH of cell manufacturing.