Global automotive supplier Marelli is introducing a range of battery management technologies for electric vehicles with advanced Wireless Distributed Battery Management System (wBMS). The system will go into production later this year, with customer launches planned for 2024.

This technology eliminates the wired physical connections typically needed in other BMS architectures, allowing for greater flexibility, increased efficiency, improved reliability and reduced costs, all crucial aspects in electric vehicles. It reduces wiring harness in EVs by about 90 percent and simplifies the battery cell construction and installation, says Marelli.

"Wireless BMS is a real game-changer, eliminating the need for the battery harness, wires and connectors associated with the standard wired BMS systems", said Dr Razvan Panati, Head of Power Electronics Technology of Marelli's Vehicle Electrification Division. Marelli has designed both the wBMS and the Wired BMS with identical base architectures, supported by two different ways of communication and interfaces.

"In that way our technology can be applied across multiple vehicle platforms with minimal change. This flexibility of the solution guarantees significant reduction in engineering costs and allows Marelli to make this high-end technology affordable for the mass market", he added.

The solution eliminates the need of daisy-chain communication and wiring by using wireless technology to enable the communication between batteries and control unit. That way, the wBMS reduces complexity in the assembly and grants more flexibility for battery modules placement.

Further, reduced weight due to connectors removal allows for more energy efficiency, thus increasing the driving range of the vehicle with the same charge. The solution also opens up room in the battery pack to allow larger batteries to fit, guaranteeing versatility, scalability, optimization; ultimately, under the right circumstances, larger batteries also translate to enhanced power performance and again extended vehicle range.

The Marelli wBMS can be delivered with a highly sophisticated software application layer that uses advanced algorithms based on a proprietary technique so-called "Sensor Fusion". The algorithms estimate several crucial parameters of each battery cell – including State of Charge, State of Health, State of Power – to ensure a more accurate calculation of the battery overall status, and informs the other components of the powertrain accordingly.

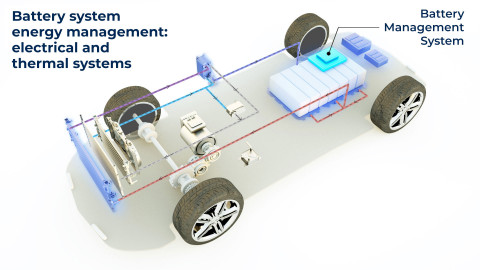

Complemented by proven e-powertrain and thermal design competencies, the battery management capabilities contribute to Marelli's integrated approach, aimed to assure flexible and customizable solutions to control, manage and optimise the energy balance in EVs.

Read More