Independent lithium-ion cell manufacturer, Imperium3 New York ( iM3NY) on Thursday (August 11) officially began the commercial cell production activity for the first US-owned lithium-ion cell manufacturing plant in New York.

Located in Endicott, NY, the 22,000 sq. meter Li-ion battery manufacturing facility will initially produce several thousand cells by September which will be ramped up to 15,000 cells/day as production scales up to reach an annual production rate of 1.8GWh.

"The iM3NY team has put in huge effort to achieve this major milestone of commercial production with iM3NY being North America's only pure home-grown battery plant," said Chaitanya Sharma, CEO, iM3NY.

With this milestone, the iM3NY project marks North America's largest home-grown Li-ion cell manufacturing factory and the only non-China supply chain capable of meeting domestic as well as global demand.

"Despite a challenging global environment and supply chain issues, we have successfully started production close to schedule which is a major achievement. We now look forward to increasing production rates toward and over the gigawatt-hour mark," Sharma added.

The first batch of cells produced will be tested for quality assurance before the sales begin with revenue expected in late September. The company expects to have annual manufacturing levels to a point where it can reach annual production levels of 1 GWh by the end of 2023 and continue to ramp up to 1.8 GWh before increasing the annual capacity to 38 GWh by 2030.

Magnis Energy Technologies Ltd (Magnis) along with its joint venture and technology partner Charge CCCV LLC (C4V) are the major shareholders in iM3NY.

The BMLMP chemistry and prismatic cell design are licensed and patented Charge CCCV technology. It contains Lithium Mixed-Metal Phosphate (LMP) with Biomineralization to yield BMLMP. iM3NY claims the BMLMP technology enables one of the highest voltages of any Li-ion cells in the marketplace at 3.9 volts -- 20% higher than Lithium Iron Phosphate (LFP) cells and 5-8% higher than Nickel Cobalt Aluminum (NCA)/ Nickel Manganese Cobalt (NMC) cells. A notable feature is that there is no Cobalt and Nickel in this high-performing cell.

The cell chemistry incorporates traditional electrolytes with a patented mixed metal phosphate composition in the cathode that contributes to the overall safety and high performance, iM3NY stated. The iM3NY manufacturing lines are capable of not only manufacturing at high volumes but are also optimized for future technologies such as solid-state batteries.

"About six years ago, C4V and Magnis had the vision to produce American-made lithium-ion batteries at a large scale using the BMLMP technology which possesses many advantages in the current marketplace," said Dr. Shailesh Upreti, Chairman iM3NY and President, C4V.

"Today, that vision has become a reality and we are working hard to scale up towards double-digit gigawatt-scale production to continue to lead our position in the US market."

The company added that it has carefully selected supply chain partners and uses hydroelectricity for its manufacturing processes to ensure iM3NY batteries are among the greenest in the marketplace.

Studies indicate the US battery manufacturing capacity is expected to grow three-fold to 224GWh by 2025 aided by favorable policies and government support.

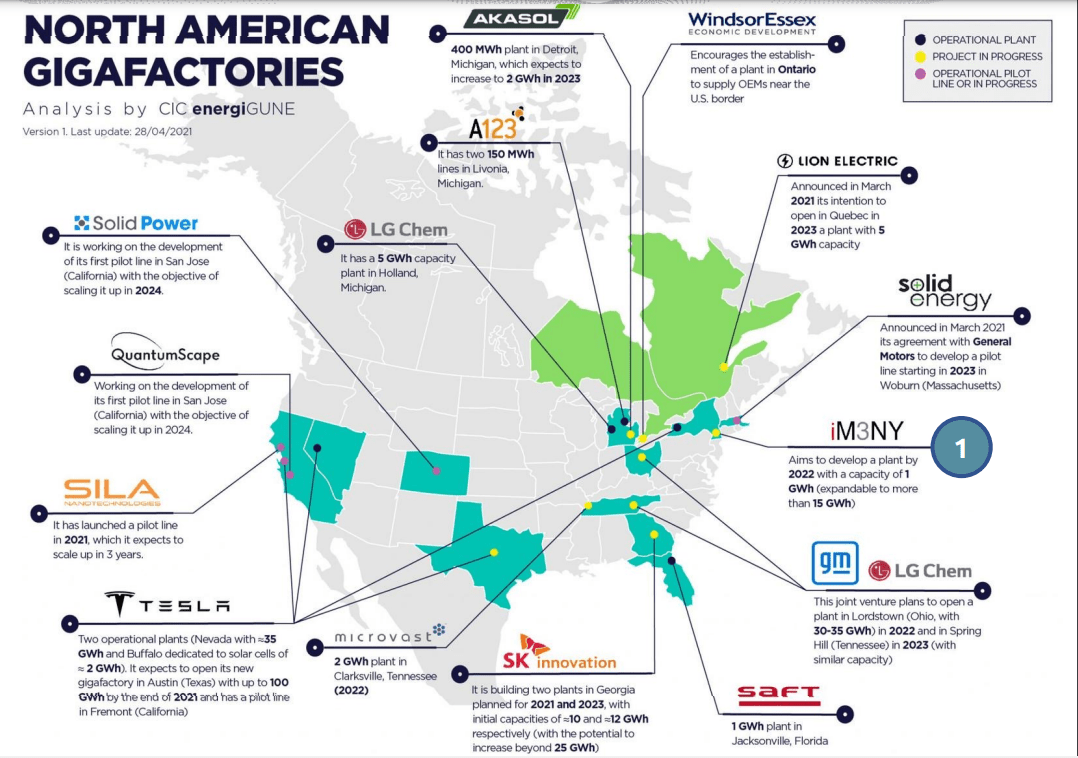

iM3NY giga factory in NY is among the few gigafactories in the US to be operational as early as 2022, the majority of factories are scheduled to begin commercial operations by 2023-24.

Read More