Cummins Group in India unveiled commercial vehicle industry's first fuel-agnostic platform, and its diversified range of hydrogen and battery-electric technology power solutions at Auto Expo 2023 in India Expo Mart, Greater Noida.

The exhibits were in sync with the company's 'Destination Zero' strategy to life by unveiling low-zero to zero-carbon emission products focusing on decarbonization of the heavy vehicle industry.

Speaking at the launch event, Ashwath Ram Managing Director Cummins Group in India said, "We share India's vision of 'Energy for Sustainable Growth' and achieving net zero carbon emissions by 2070. With a promising combination of our strong, global technological expertise and our deep understanding of the India market due to our 60 plus years legacy, we are well positioned to contribute toward India's aim of becoming a cleaner and greener 'Atmanirbhar Bharat'".

RELATED: Cummins, Tata Motors to collaborate on hydrogen, battery-electric propulsion techs

He added, "we understand that the road transport sector has a major role to play in helping reduce emissions so India can meet its climate goals and we are deeply committed to play our part in powering nation's decarbonization journey. Our innovations reaffirms our commitment to Decarbonization. We will continue to work together with our stakeholders on low carbon and zero emissions solutions that further our shared goal of reducing our carbon footprint on the planet."

'Destination Zero' is part of the framework of Cummins' broader 'PLANET 2050' environmental sustainability strategy, which also includes a focus on improving the communities the company operates in and using natural resources in the most responsible way.

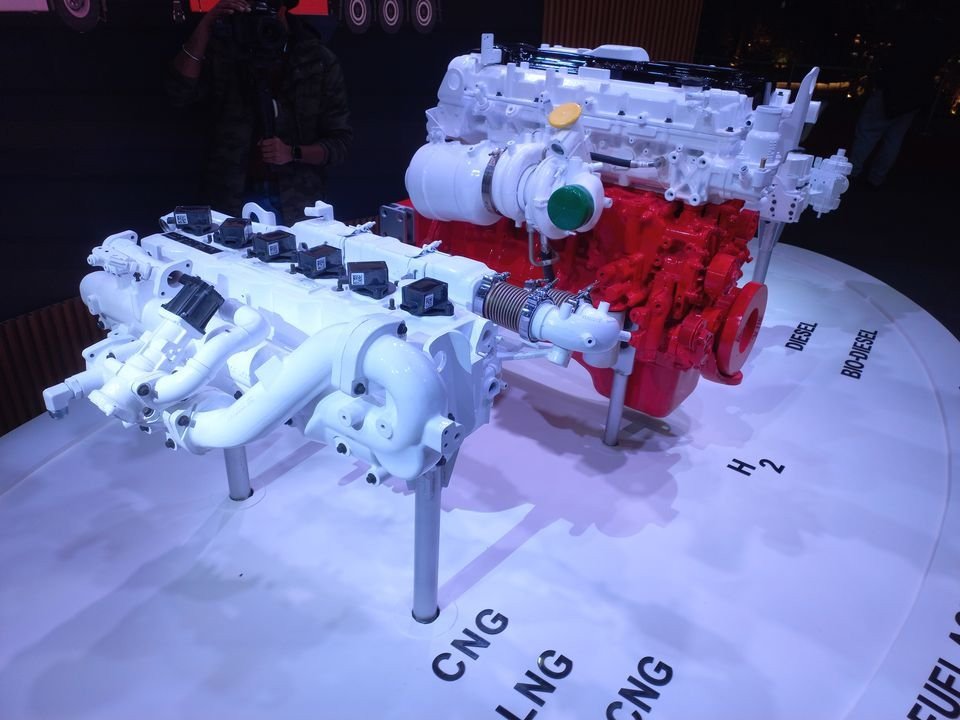

Innovative Fuel Agnostic Platform Engine

Cummins' fuel-agnostic ICE engine architecture utilizes a common base engine with cylinder heads and fuel systems specifically tailored to fuel ranging from diesel, natural gas, renewable natural gas, and hydrogen. The platform offers OEMs common engine architecture across multiple fuel types resulting to a high degree of parts commonality.

Hydrogen Internal Combustion Engine (B6.7H Engine)

Part of the fuel agnostic platform, Cummins' hydrogen internal combustion, when paired with green hydrogen, produces zero 'Well-To-Wheel' CO2 emissions. Moreover, it has an industry leading 700 bar Hydrogen tank that enables quick refueling.

With the B6.7H engine, Cummins has addressed the medium- and heavy-duty trucks and buses segment, thus highlighting the technology's ability to support decarbonization across multiple duty-cycles.

Hydrogen Electrolyzer (for Green H2 Generation)

Electrolyzer takes the water as input and splits it into hydrogen and oxygen as output. When supplied with renewable energy, the H2 generated is called as green H2 since the process doesn't have any carbon footprint.

Cummins has supplied and commissioned more than 600 electrolyzers worldwide with PEM and alkaline technologies. Cummins displayed a modular variant of the state-of-the-art electrolyzer-stack technology at the auto expo.

Hydrogen Fuel Cell

Cummins' latest generation fuel cell engine showcases rapid evolution of its zero-emissions technologies. For customers that need and want to reach zero greenhouse gas emissions today, hydrogen fuel cells would be an apt solution when supplied with green H2 as fuel.

Building on the deployments of more than 2,000 fuel cells globally for various applications including bus, truck, stationery power and railways, this next generation product provides improved power density, efficiency and durability and is available in single (rated power - 125kW) and dual module (rated power – 240kW) engines for both medium- and heavy-duty vehicles that can work in diverse working environments from -30 °C to 45 °C with 60 percent peak efficiency.

Battery-electric Technology (Battery-LFP and NMC)

Drawing on deep duty cycle and application experience, Cummins has developed the new generation battery pack solutions. Cummins is showcasing multiple batteries that help the customers to reach zero-emissions today.

These Lithium ion batteries are with distinct chemistries like Lithium Iron Phosphate (LFP) and Nickel Manganese Cobalt (NMC) that optimizes to serve diverse needs of charging time, weight, range and cost economics of variety of applications in the market.

RELATED: Cummins Inc. invests $24 million in VoltStorage, to advance the Destination Zero strategy

Cummins batteries are equipped with advanced BMS for monitoring various critical battery parameters, diagnostics and improve the battery life and performance.

Electric Powertrain Technology (14Xe ePowertrain)

Cummins recently announced its acquisition of Meritor, a leading global supplier of drivetrain, mobility, braking and electric powertrain technologies. The addition of Meritor strengthens Cummins' industry-leading range of powertrain components and will enable accelerated development of electrified power solutions.

The 14Xe ePowertrain is designed for scalability and can be adapted to fit various electric powertrain needs based on the vehicle application and duty cycle. Its design provides high-efficiency, lower weight and better turning radius. Thus it enables, longer vehicle range by integrating the motor and transmission into the axle, thereby freeing up space for more batteries.

Images Source: Source: Dhiyanesh Ravichandran - ETN

Read More