Israeli firm StoreDot has said that its advanced silicon batteries will go into manufacturing very soon, thus enabling car makers to design and produce cheaper, lighter and more sustainable EVs. With its XFC technology, OEMs will be able to optimize a vehicle's weight and cost, rather than pushing for ever greater range and battery size, according to the company.

It is said that StoreDot is on track to deliver its '100in5' silicon-dominant extreme fast charging batteries to EV OEMs by next year. This transformative technology will deliver 100 miles, or 160 km of range in just five minutes of charge, it claims.

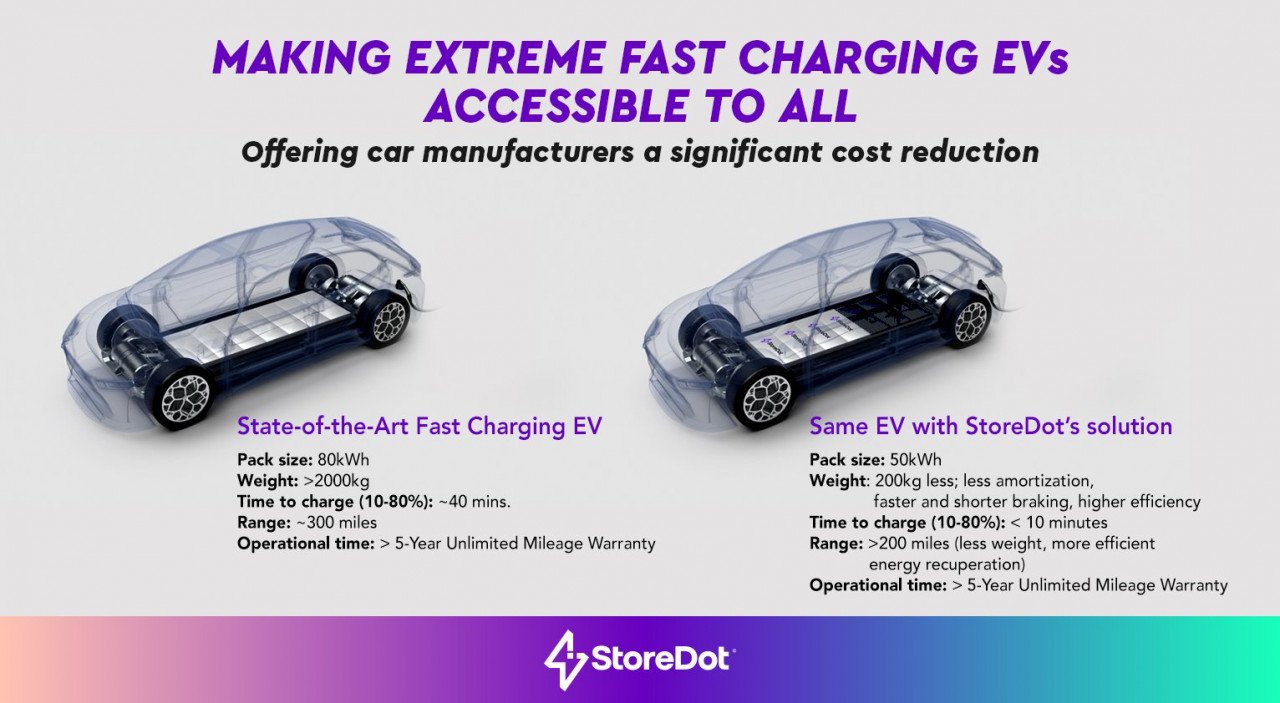

The technology has reached sufficient charging and discharging cycles that it will enable vehicle manufacturers to include a smaller battery pack, StoreDot adds. Smaller packs with extreme fast charging (XFC) technology translate into improved EV specifications including better car efficiency, increased utilization of regenerative braking, reduced carbon footprint and lower costs, further resulting in affordable and lighter EVs to enhance higher adoption and transition.

Dr Doron Myersdorf, CEO of StoreDot, commented, "Up until recently OEMs were increasing the size of battery packs in their EVs because a proportion of drivers were transitioning from gas to electric for the first time with the known 'range anxiety' in their minds. Those drivers, and anyone who is an EV advocate now realize that range anxiety is no longer the most pressing issue - and won't even be an issue at all once public charging infrastructure around the world is properly in place".

Electreon, Toyota, DENSO to co-develop Wireless EV Charging Technology

Read More