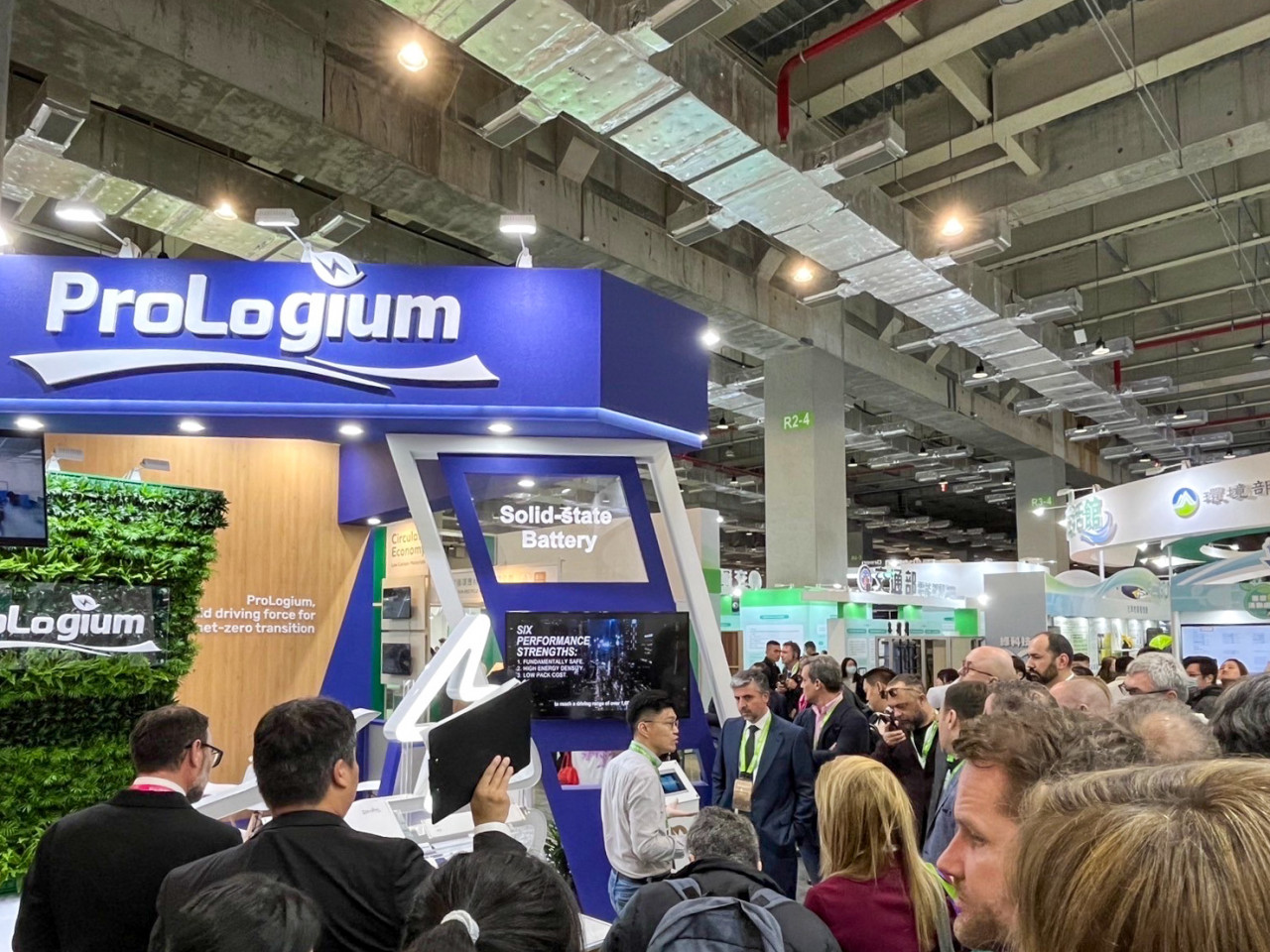

Solid-state battery developer ProLogium recently showcased its exclusive 'P-C-R' next-generation solid-state battery solution at the 2050 Net Zero City Expo in Taipei, Taiwan, aiming to develop solid-state batteries that are not only commercially competitive but also sustainable for emerging global needs.

The latest battery harmonizes performance, cost and resource circularity to maximize resource efficiency and cost-effectiveness, claims the battery firm. Beyond its performance advantages, the unique structure of ProLogium solid-state batteries enhances recycling capabilities, addressing the significant challenges posed by conventional lithium-ion battery recycling, it adds.

The company cites the risks of fire and explosion and the complexities of dismantling and material recovery, which often result in only high-value metals such as cobalt and nickel being reclaimed from cathodes. In contrast, ProLogium's solid-state batteries are structurally stable, allowing for easier disassembly of battery packs into the smallest units and a more straightforward recycling process.

According to its recycling plan, apart from high-value metals, solid electrolytes, silicon anode materials, and conductive materials can also be recycled, thereby achieving greater energy efficiency, minimal pollution, and enhanced resource circulation, ProLogium claims.

Further, the company plans to continuously enhance manufacturing efficiency at its recently opened Taoyuan plant and optimize battery cell design, including increasing energy density and adopting a pure silicon anode to reduce carbon emissions.

The objective is to achieve a 23.2 percent reduction in manufacturing carbon emissions within three years, with a long-term goal of an 83.8 percent reduction over the next decade. Key to these achievements for lower-carbon emissions are the adoption of high-efficiency, low-carbon processes and equipment, focusing on sustainable electricity, material sourcing, and building a recycling value chain as part of its expansion strategy.

Also, at the Taipei expo, ProLogium unveiled the exterior design of its upcoming Dunkirk gigafactory and its strategies to minimize environmental impact at the plant level. This includes efforts to reduce energy and water consumption, while prompting the shift towards electric transportation, in collaboration with the electric vehicle value chain.

ProLogium opens solid-state lithium ceramic battery plant in Taiwan

Read More