Germany's BASF, Korea's SK On agree to jointly evaluate global lithium-ion battery market

German company BASF, a leading global producer of battery materials, has entered in an agreement with leading global electric vehicle battery cell manufacturer SK On. The two companies will jointly evaluate collaboration opportunities in the global lithium-ion battery market, with a focus on the North America and Asia-Pacific markets.

The companies will initially evaluate collaboration in the production of cathode active materials (CAM), before exploring other collaboration opportunities, including battery recycling, at a later stage.

In a release, BASF said the collaboration would bring together the strong business and product development capabilities of both partners and help develop industry-leading battery materials in the lithium-ion battery space. BASF estimates the global automotive battery materials market will grow by 22 percent a year till 2030. The German chemicals major believes cathode materials -- the most complex and expensive chemical component of an automotive battery -- and battery recycling will together give it more than €7 billion in annual sales by 2030.

BASF is already a leading supplier of advanced CAM to the global the lithium-ion batteries market. Earlier this year, it opened what it calls Europe's first co-located center for battery material production and battery recycling at Schwarzheide in Germany. BASF said the plant will supply products tailored to the specific needs of cell manufacturers and automotive OEMs in Europe. The company also offers base metal sourcing and management as well as closed-loop battery recycling solutions.

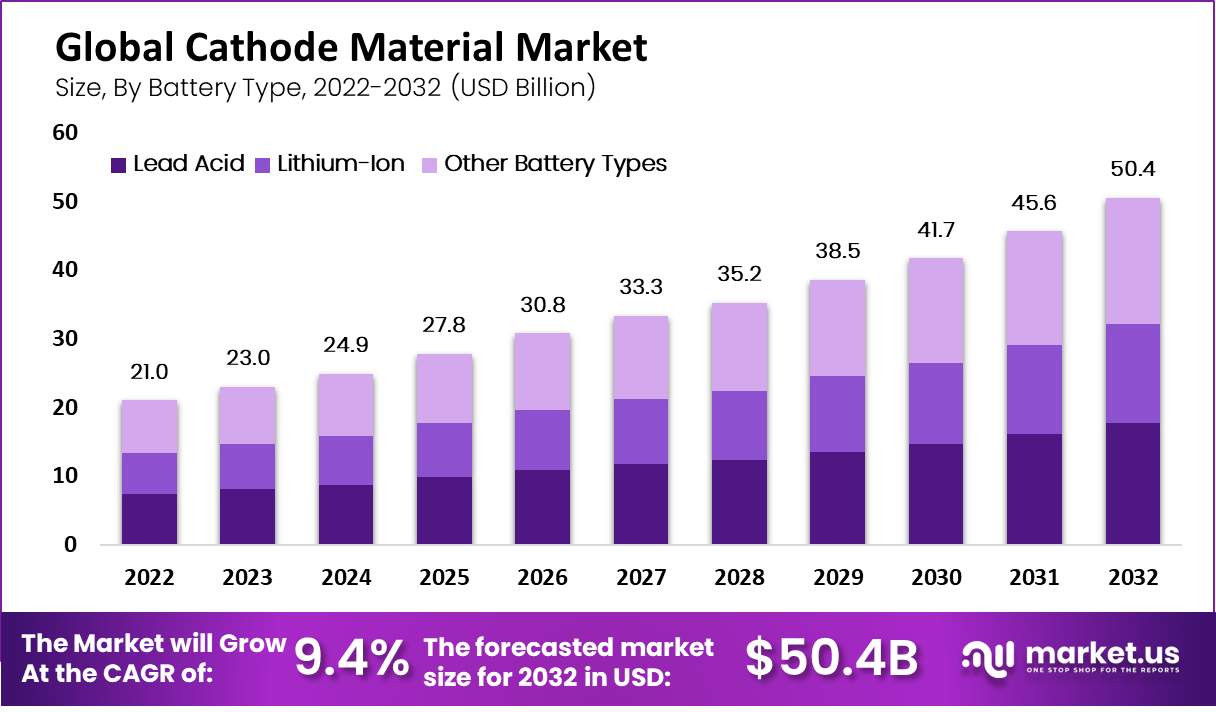

The demand for cathode materials is driven largely by growth of electric mobility: although cathode material end-use occurs in consumer electronics, automotive, and other areas, it is mainly the global switch to battery EVs and plug-in hybrid EVs that has driven incremental demand for the material. Research company Market.us estimates the market will cross $50 billion by 2032.

"With the collaboration with SK On, we are further strengthening our market position to serve battery manufacturers and electric vehicle producers around the world." said Dr. Peter Schuhmacher, President of BASF's Catalysts division, who also holds responsibility over its battery materials and battery recycling verticals. "We want to address the need for more sustainable solutions for the electric vehicle industry. And we are ready to work with our customers and partners in all regions to make this a reality."

"The collaboration with BASF is part of our efforts to bolster battery materials supply chain," said Jee Dong-seob, President and Chief Executive Officer of SK On. "We look forward to expand our partnership to lead the global EV battery market."