Umicore, ACC inks pact for li-ion battery recycling technologies

Umicore has announced the signing of an agreement with Automotive Cells Company (ACC) on battery recycling services for the needs of the ACC pilot plant in Nersac, France.

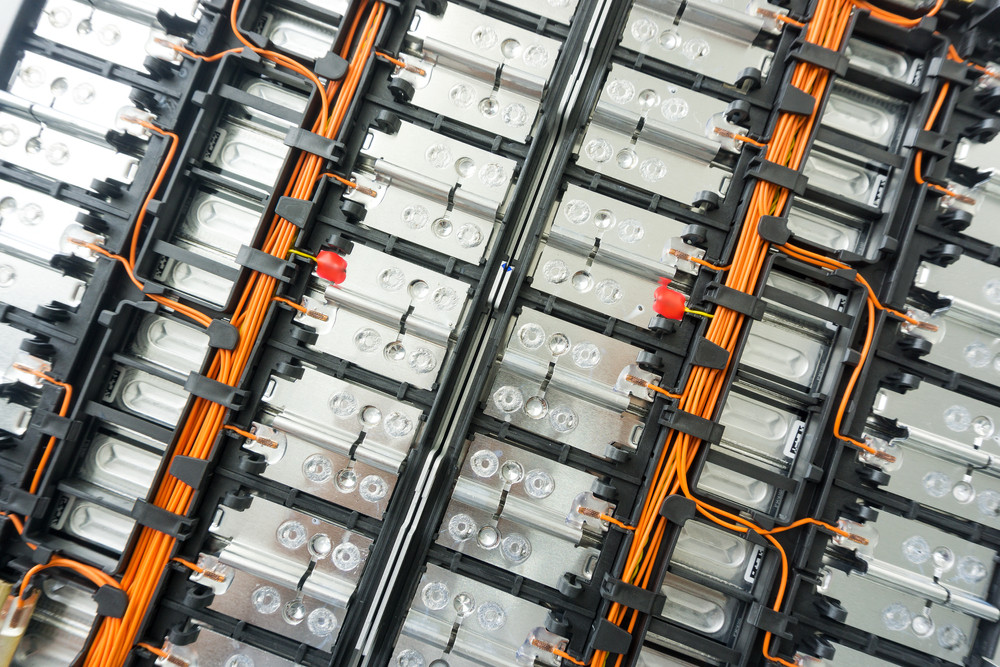

The plant started operations in 2011 to treat portable electronics batteries and the first generations of EV batteries. Since then, its processes and underlying recycling technologies have continuously improved and today reflect the combined know-how gains that Umicore has made during more than one decade of Li-ion battery recycling.

In 2022, Umicore will introduce the latest generation of its proprietary recycling technology. This process marks a significant step-up in recycling performance with an optimized operating window for EV batteries, demonstrating:

- The significantly improved metallurgical process with an increased extraction efficiency of cobalt, nickel, and copper to now reach over 95% yield for a wide variety of battery chemistries.

- First-of-its-kind technology to recover most of the lithium, solving a key constraint of today's existing recycling flowsheets.

- Automated material flow minimizing manual handling to further increase process robustness and efficiency.

The recovered metals will be delivered in battery-grade quality at the end of the Umicore recycling process allowing them to be re-circulated into the production of new Li-ion batteries.

This newest generation technology will be available for the market in 2022 and ensures minimal waste and impact on the environment, which will be vital for the surge in EV car adoption.

Umicore also announced the signing of an agreement with Automotive Cells Company (ACC) on battery recycling services for the needs of an ACC pilot plant in Nersac, France.

ACC will benefit from the new Umicore technology through the announced partnership, underlining the importance of a European supply chain for the success of car electrification in the region.

Denis Goffaux, Executive Vice President of Umicore said "By recovering key critical elements for the Li-ion battery supply chain, such as lithium, cobalt, nickel, and copper, in the most efficient and environmentally friendly way, Umicore is leading the way towards a battery circular economy, providing solutions to the growing demand for sustainably sourced materials while lowering their CO2 impact. The agreement with the ACC pilot plant in Nersac is reinforcing the standard when it comes to sustainability and demonstrates our strong commitment to providing our customers with solutions for production waste and end-of-life materials. Battery recycling is a key ingredient of sustainable electric mobility and is fully in line with Umicore's overall closed-loop philosophy."

Automotive Cells Company (ACC) was founded in August 2020 and to date combines the expertise of two major companies with complementary skills and experience: Stellantis and TotalEnergies. ACC is supported by the French, German and European authorities. Its ambition is to become the European market leader for car batteries.

Gilles Tardivo, Nersac Pilot Plant Vice-President of ACC said "Our pilot line in Nersac aims to test all our product and process solutions before mass production in our future Gigafactories. The agreement between ACC for Nersac and Umicore fits perfectly into this framework, allowing us to improve our expertise, locally, regarding the recycling of our production waste. This is an important step in our larger policy of recycling our future batteries."