Morrow Batteries opens its first GW-scale LFP battery facility in Norway

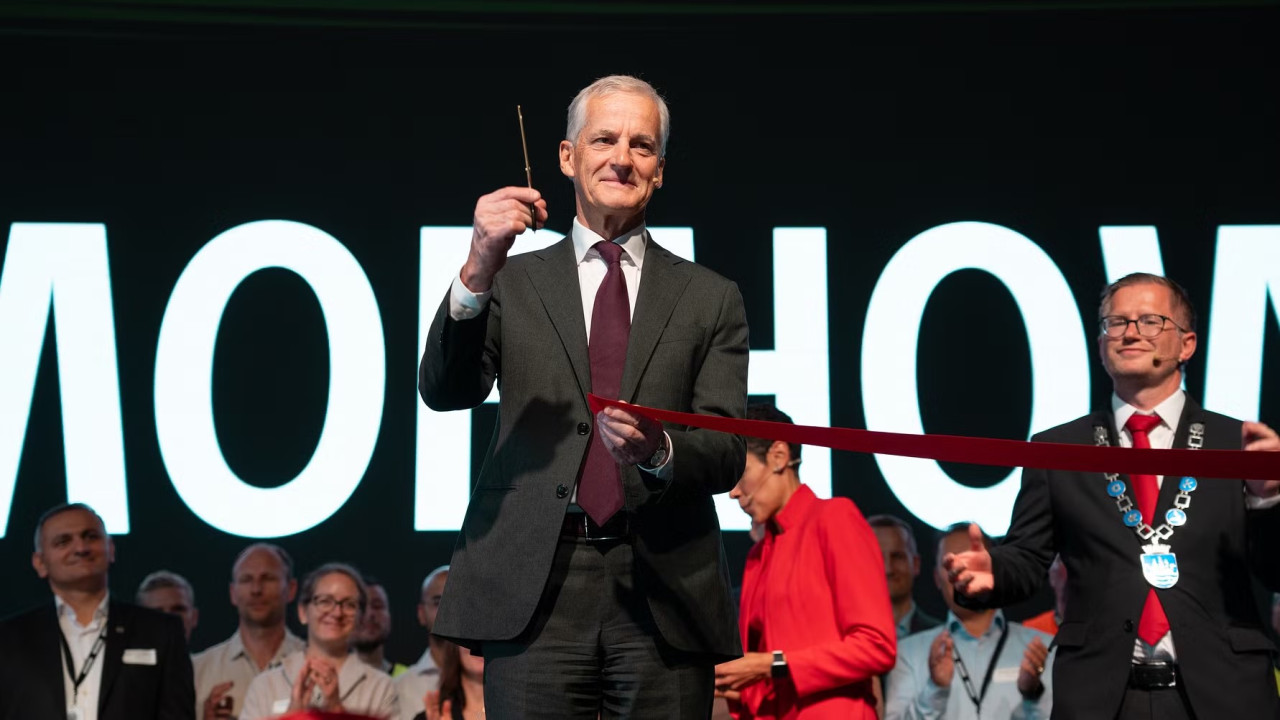

Morrow Batteries is gearing up to be the first European manufacturer of prismatic Lithium Iron Phosphate (LFP) batteries later this year. The company recently inaugurated its first gigawatt-scale facility in Arendal, Norway, in the presence of Norway's Prime Minister Jonas Gahr Støre.

With this facility, the company will be able to produce up to 3 million battery cells annually or 1 GWh capacity. Test production has already started, and Morrow will work closely with customers to fine-tune the production equipment to achieve serial production quality over the following months.

Morrow claims the facility to be the Europe's first gigafactory for LFP batteries. It will also be the first of four factories planned in Arendal. "This is a hugely important day in Norwegian industrial history and a testament to the bold vision and risk-taking spirit of our founders and the dedication of our diverse team of Morrowers, now consisting of 200 individuals from 34 nationalities", said Lars Christian Bacher, CEO of Morrow Batteries.

"Our achievements today would not have been possible without the unwavering support from the Arendal municipality, local and national government, and our committed shareholders. Together, we are paving the way for a sustainable energy future to make Europe more competitive and safe", he added.

He further added, "As a result of the efforts put in by many, Arendal has become the first city in Europe to host a giga LFP factory, contributing jobs, value-creation, and positioned for significant export revenues. We look forward to delivering the first commercial batteries to customers by the year's end".

Since November last year, Morrow claims to have rolled-out thousands of LFP sample cells to potential customers for testing and validation at the company's Customer Qualification Line (CQL). The company now aims to deliver a commercially viable, thoroughly tested, competitive LFP product.

Norway is emerging as a suitable place for battery manufacturing because of its process industry and material technology industrial track record, a long tradition of engineering and industrial innovation, abundant access to renewable power and a competent labour model.