BASF bags German funding approval for 54 MW electrolyzer

German chemical company BASF has received funding approval for a 54 MW proton exchange membrane (PEM) electrolyzer that will have produce up to 8,000 metric tons of hydrogen per year.

Approvals were received from the German Federal Ministry for Economic Affairs and Climate Action for up to €124.3 million, of which, up to €37.3 million will be financed by the government of Rhineland-Palatinate.

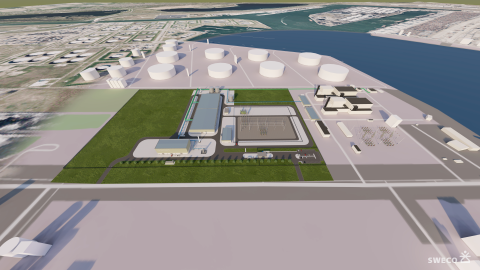

Work on the so-called Hy4Chem-EI project coming up at the Ludwigshafen site is now entering the next phase of construction in co-operation with Siemens Energy, and the two partners expect to begin operating the water electrolysis plant in 2025.

Once operational, the electrolyzer will be among the largest of its kind in Germany. The system will be powered by renewable energy and produce green, or CO2-free hydrogen reduce greenhouse gas emissions at the site by up to 72,000 metric tons a year.

BASF plans to use this hydrogen primarily as a raw material in the manufacture of products with a reduced carbon footprint. The company said it would also supply the hydrogen for mobility in the Rhine-Neckar Metropolitan Region to support the ramp-up of a hydrogen economy in the area.

Dr. Melanie Maas-Brunner, member of the Board of Executive Directors of BASF SE and Site Director, Ludwigshafen, said: "… our main need for low-carbon hydrogen is as a raw material. In the long term, it will also become increasingly important for BASF as an energy vector."

Hydrogen is the starting point for important chemical value chains. At the Ludwigshafen site, BASF uses around 250,000 metric tons of hydrogen per year at the Ludwigshafen site, which is produced by steam reforming (generates high CO2 emissions) or as a coupling product and by-product.

Changing the technology for producing hydrogen and using this hydrogen as a raw material for chemical products should significantly reduce BASF's carbon footprint – the company has set itself a target of achieving net zero by 2050.

The company is also testing other technologies, including a demonstration plant for electrically-heated steam cracker furnaces and a methane pyrolysis test plant, in attempts to rein in emissions.