Rio Tinto, InoBat partners for li-ion battery manufacturing and recycling in Serbia

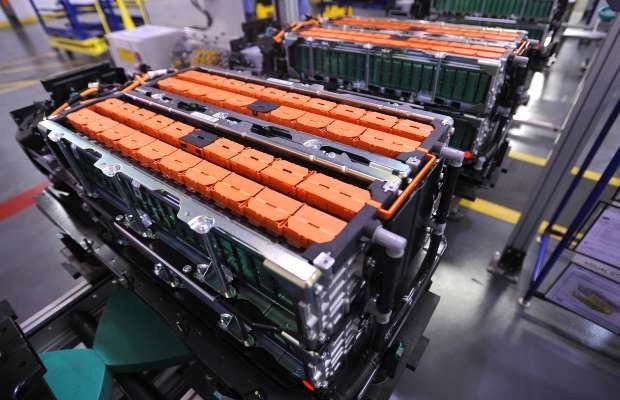

European battery technology and manufacturing company, Rio Tinto and InoBat have signed a Memorandum of Understanding to work together to fast-track the establishment of a "cradle to cradle" battery manufacturing and recycling value chain in Serbia. The partnership will cover the full commodity life-cycle from mining through to recycling of lithium.

Rio Tinto's Jadar project in Serbia, one of the largest greenfield lithium projects in development, has the potential to produce approximately 55 thousand tonnes of battery-grade lithium carbonate in Europe, one of the world's largest growing electric vehicles markets.

InoBat, a European-based battery manufacturer with a battery research and development facility and pilot plant being developed in Slovakia intends to scale up its future production, through gigafactories to be built in the EMEA region. InoBat's goal is to aid the European market with innovative energy solutions, including the production and recycling of electric vehicle batteries.

Managing director of Rio Tinto's borates and lithium businesses, Marnie Finlayson said" This collaboration with InoBat will enable an important exchange of knowledge and information on lithium processing, recycling, and technologies for the next generation of batteries. It is a visionary initiative and one that is aligned with Rio Tinto's commitment to partnerships that provide solutions to combat climate change."

It is envisioned the collaboration between Jadar and InoBat will also boost the development of a complete European lithium and electric vehicle battery value chain that will harness and enhance local skills, environmental, social, and governance standards, and cross-border interactions for the benefit of Serbia and other European economies that wish to collaborate.

Marian Bocek, Chief executive officer of InoBat Auto said "The signing of Memorandum of Understanding with Rio Tinto represents an important step in achieving InoBat's goal to utilize a European-based value chain and support European bid for technological independence. Our unique "cradle to cradle" approach covers the whole life-cycle of batteries from mining to recycling, to underpin circular economy efforts and the Agenda 2030 Sustainable Development Goals."

In 2020, Rio Tinto approved an investment of almost $200 million to complete the final phase of the study at the Jadar project, which is expected to be finalized in 2021, with an investment decision to follow. The scale and high-grade nature of the Jadar deposit provide the potential for a mine to supply lithium products into the electric vehicle value chain for decades. If approved, construction of a mine to the highest environmental standards would take up to four years and would be a significant investment for Serbia with direct and indirect economic benefits to the Serbian economy.