Determining the authenticity of cells & batteries in the global market

As the demand for Li-ion batteries grows globally, the market for counterfeit Li-ion batteries continues to expand rapidly. In this article, researchers at Underwriters Laboratories discuss the counterfeit battery market, the quality and safety of counterfeit cells and batteries, ways of detecting them, and considerations for avoiding these products.

The increasing demand for lithium-ion batteries in a myriad of applications can be attributed to their high energy density, high power capability, long service life, and low cost. The inherent advantages of batteries and the incentives promoted by governments to purchase electric cars have led many countries to increase investment and production of batteries and their components. The growing awareness to limit greenhouse gas emissions to promote a cleaner environment has also led to the rapid installation of alternative energy sources along with grid energy storage systems that use different battery chemistries.

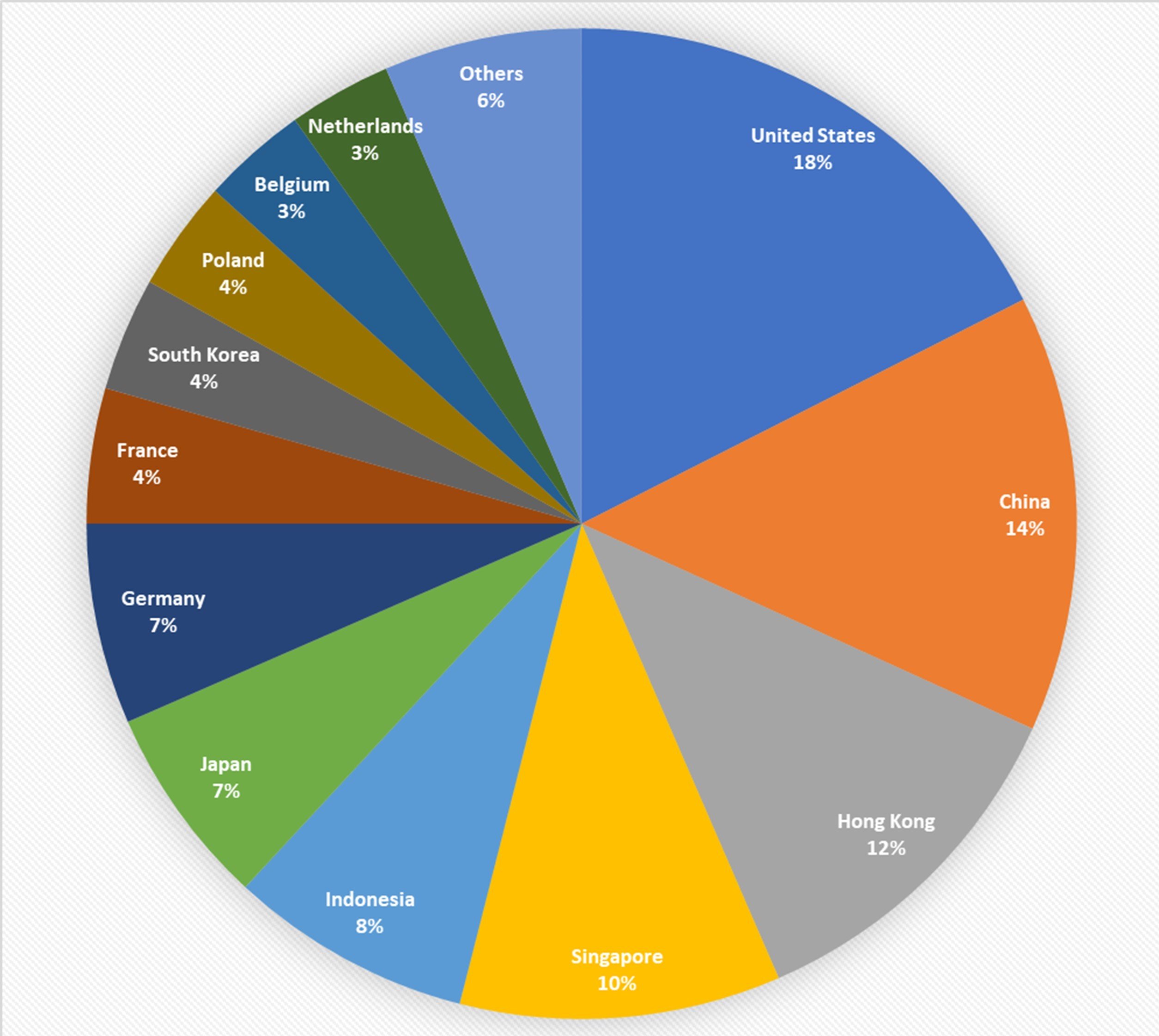

The production of batteries is increasing globally. Although the exact number of batteries produced by the country is not readily available, this factor can be indirectly measured based on annual battery sales. The 12 countries that exported the highest dollar value worth of Li-ion batteries during 2020 are shown in Figure 1. Although the United States is one of the largest exporters of Li-ion batteries in the world, its great challenge today is access to raw materials. China, despite being the second-largest exporter, does have the raw materials to manufacture the batteries.

According to energy storage news, the European Commission approved $3.52 billion in funding to support research into four core stages of battery manufacturing: the mining of raw materials, battery cell design, battery systems, and recycling in the supply chain. Thanks to this economic incentive, it is expected that by 2025, Europe will become the world's second-largest Li-ion battery cell producing region.

China outpaces the US in battery production today, with 93 mega-factories producing Li-ion batteries, compared to just four in the US, as indicated by Benchmark Mineral Intelligence. If China continues to manufacture and supply Li-ion batteries at the current pace, it is expected to have 140 mega-factories by 2030.

The largest global companies that supply Li-ion batteries and the location of their global headquarters are as follows.

- Anco Macao Commercial Offshore Li (Macau)

- Black & Decker Suzhou Precision (China)

- Chervon Limited (Hong Kong)

- Samsung SDI Co Ltd (South Korea)

- Sanyo Electric Co Ltd (Japan)

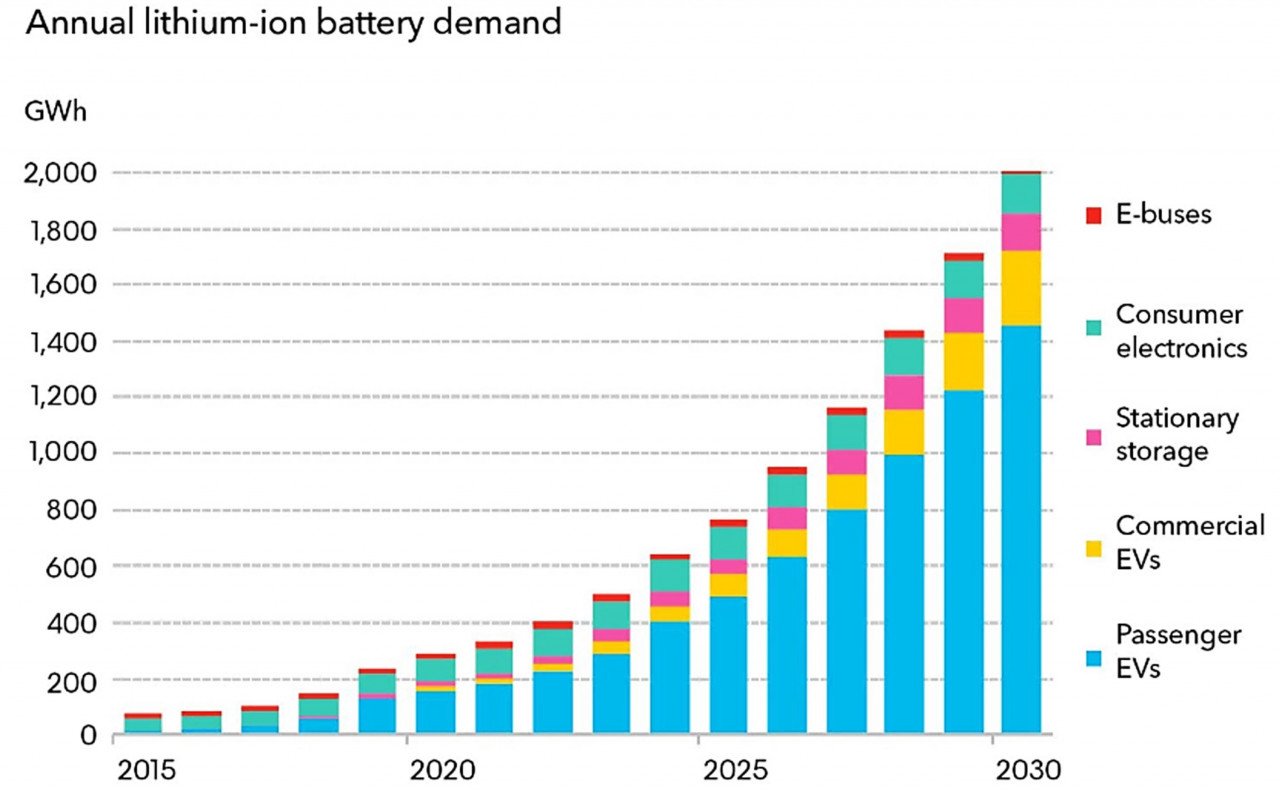

According to the Bloomberg NEF, the Li-ion battery demand forecast for the next 10 years is shown in Figure 2. It is important to analyze not only the production of Li-ion batteries but also their end-use. The great clean energy boom has caused the governments and automotive sectors to focus on electric vehicles (EVs). This has increased the demand for batteries in this sector and it is expected that by 2030 it will cover 70 percent of total production consumption.

Authentic & counterfeit battery market

The widespread demand for Li-ion cells and batteries has attracted and given rise to illicit copying to profit through counterfeiting. Counterfeit cells and batteries have been in existence for a long time, but they have become more prevalent today due to the very lucrative business created with the exponential demand for Li-ion batteries. Counterfeit cells are manufactured by imitating high-quality and authentic cells and sold at a significantly lower cost. This is done to deceive customers into believing that the fake product provides equal or greater performance than the authentic product. These counterfeit products tend to have fake and unauthorized trademarks or logos, have low-quality components, and are not certified to any standards that may make them impossible for customers to differentiate. This seriously compromises the safety, quality, and performance of the products and poses many health and safety risks to customers.

The average user who buys good quality, authentic Li-ion cells or batteries usually does not find the need to report it. The scenario changes when a user comes across a counterfeit cell. The affected user usually makes it public in a negative review or by not recommending it. It should be noted that our search found no traceable statistics on original batteries, but there are plenty of reports on counterfeit or poor-quality cells. The sale of counterfeit batteries does not always happen on websites of dubious origin. There are reports of people using Li-ion cells obtained from reputable e-commerce channels, that have failed even under 'normal' operating conditions. In many of these cases, the people affected by these incidents cannot come to any settlement because neither the vendors nor the distributors want to be held responsible for the incident.

In the vast worldwide network of original equipment manufacturers (OEMs), distributors, sellers, and resellers, it can be almost impossible to know who is responsible for the evaluation of the cell and battery quality as well as the safety associated with them. In some cases, the large volume of cells manufactured and handled makes it challenging to detect poor quality or counterfeit batteries. And on other occasions, the sale of the product is carried out maliciously, putting an economic interest of one person or organization before the safety of the equipment and the health of the end-user.

In a survey conducted by Red Points to an electronic consumer audience, it was found that about 76 percent of the population between the ages of 18 and 60, are unaware of the characteristics of an authentic product and tend to use the comments and reviews of other people to decide on making a purchase. An interesting fact is that 18 percent of the people surveyed admitted to having bought counterfeit products (it is not specified whether intentionally or not) and 40 percent of those people were satisfied with the purchase. The choice of higher performance over quality allows non-original items to be positioned in the market, by providing an average performance at a cheaper price.

Quality of counterfeit Li-ion cells & batteries

Li-ion cells are highly variable in terms of geometries and chemistry types. Application-specific designs of cells mean performances may vary among cells that appear similar. Since Li-ion cells are manufactured with different cathode and anode chemistries that provide varied performance, it is extremely important to understand the application-based requirements before purchasing or using any Li-ion cells. The first step in ensuring the high quality and authenticity of cells is to purchase from reputable manufacturers and authorized suppliers. Often, low-quality or counterfeit cells mimic high-quality or authentic cells and are difficult to distinguish by physical examination. Whenever possible, validation tests must be conducted on cells before use in their end applications to ensure that quality and performance requirements adhere to the application targets and manufacturer specifications. Verification of claims made by manufacturers on cell performance may not be easy to perform because they often require specific instrumentation not readily available to everyone. Some manufacturers of low-quality cells advertise performances that are not achievable by that model of a cell. Customers unknowingly purchase these items because they appear superior compared to other similar cells.

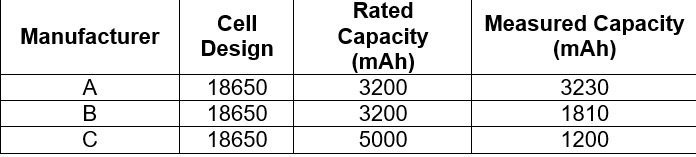

Large discrepancies between the advertised and the actual achievable performance may occur in low-quality cells. Experimentally testing performance features such as cell capacity and power can highlight these discrepancies. Cell capacity lower than one-quarter of the advertised value listed on the label from the manufacturer was experimentally measured for cells purchased online, as shown in Figure 3. In this particular example, the manufacturer's label displayed the cells' capacity at 5000 mAh while the measured capacity was only 1200 mAh.

The quality of such counterfeit products cannot be verified by mere visual inspection. Figure 4 has the photos of two battery cells with labels that look very similar but differ where the counterfeit product has an incorrect spelling of the State of manufacturing and is missing the date stamp. Manufacturers of these types of low-quality products typically lack the technical knowledge and understanding that is required for quality control, safety, and shipping.

Certifications are falsified along with misleading performance claims on the label. Figure 5 shows the photos of products that have an incorrect UL Mark demonstrating the lack of knowledge about UL certifications and marks assigned for UL-certified products. In many cases, it is challenging to distinguish an authentic certification or certification mark on a counterfeit product. Hence, caution is warranted when purchasing cells from third-party sellers on online marketplaces as well as unauthorized resellers. This directly results in compromised safety of the battery products and eventually the devices that use them.

Safety of counterfeit Li-ion cells & batteries

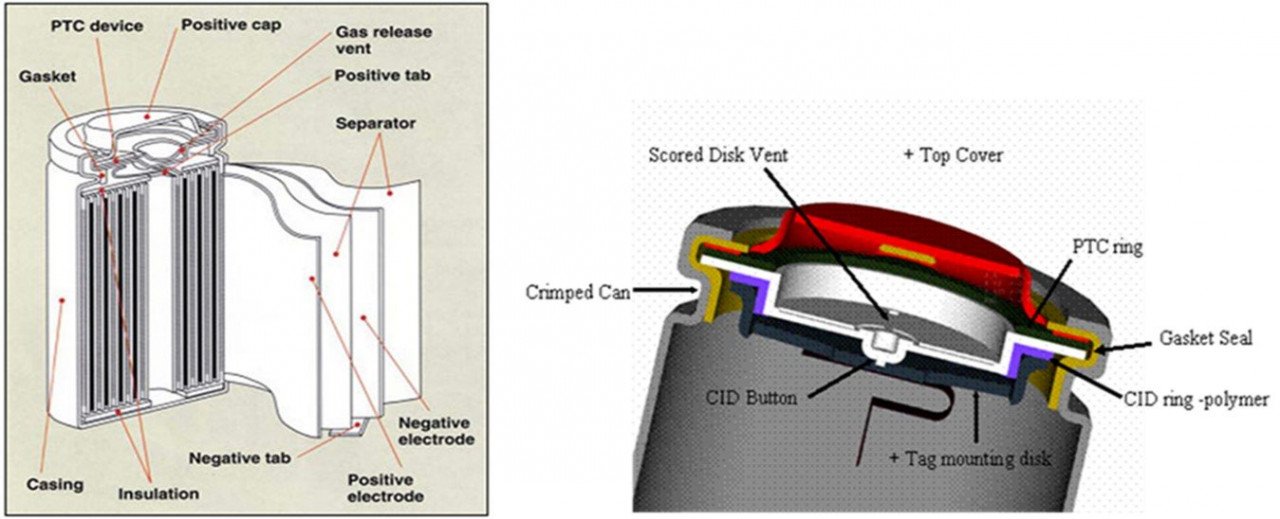

The compromise in safety with low quality and counterfeit products will be explained using the following example where 18650 model Li-ion cells were studied. The 18650 cylindrical metal can cell with an 18 mm diameter and a height of 65 mm is one of the most common Li-ion cell types. The cell consists of the anode (negative electrode), the cathode (positive electrode), the separator (physically separates the electrodes), and the electrolyte (an ion-conducting medium). The electrodes with the separator in between them are wound in a roll and inserted into the metal can, which is then filled with the electrolyte and sealed (Figure 6). (Read the detailed description of the manufacturing processes for high-quality Li-ion cells in the May-June ETN issue.)

In addition to the basic components described earlier, high-quality commercial 18650 Li-ion cells employ various built-in safety mechanisms for protection against off-nominal conditions, such as overcharging, over-discharging, extreme temperatures, as well as external and internal short circuits. Most 18650 Li-ion cells built by OEMs have at least two internal protective devices: a positive temperature coefficient (PTC) and a current interrupt device (CID). These devices, located in the cell header (Figure 6), protect the cells under external short circuit conditions and overcharge events.

The PTC consists of a thin electrically conducting polymer layer sandwiched in between two flat metal rings. In the event of an external short, the high current flowing through the PTC causes the polymer to heat and its resistance to rise sharply, reducing the current flowing through the cell. The CID, in turn, is a sophisticated construction of two metal disks that are in electrical contact only at the center point, which also provides the electrical contact between the electrode and the cell terminal. During overcharging, gas production inside the cell and the related pressure build-up causes the CID to activate and disconnects the electrical pathway. If this should fail to stop the pressure increase within the cell, the pressure is released in a controlled manner through the top vent. In addition to the PTC and CID, some commercial cells have additional protective devices such as bottom vents and protection circuits. Moreover, battery-level safety mechanisms including the BMS are used to protect batteries against off-nominal conditions.

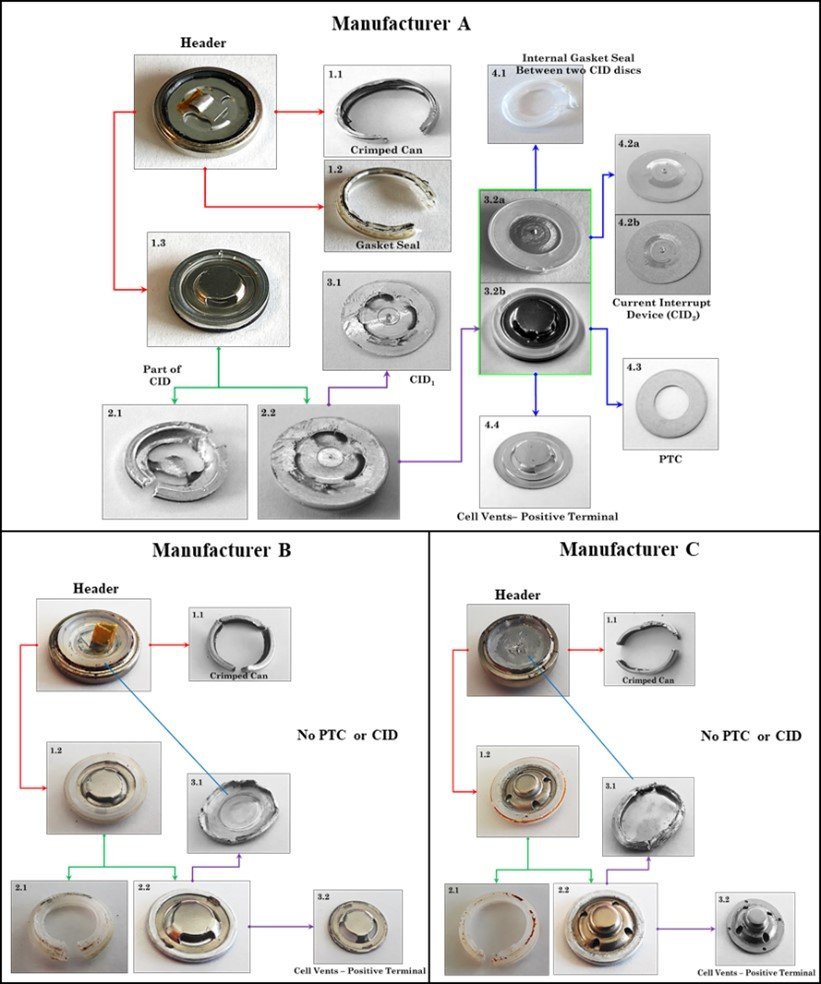

Counterfeit cells often lack these safety mechanisms and are not tested or certified to safety standards. Figure 7 shows a comparison of the header parts of three commercial cells from manufacturers A (OEM), B (counterfeit), and C (counterfeit) observed during a destructive physical analysis of the cells. The cells from the OEM contained the PTC and CID for protection against external shorts and overcharge, respectively. In contrast, neither of the counterfeit cells contained these protective devices, significantly compromising safety.

Table 1 shows the comparison of cell capacities of 18650 cells that were procured from different sources. Cells from manufacturers A and B look similar when inspected visually and are sold under the same brand names and specifications. Only upon validation tests, the discrepancies between a manufacturer's rated capacity and measured capacity were evident. Manufacturer C (Figure 3) boasts an unusually high capacity of 5000 mAh, but provides only a quarter of that capacity at 1200 mAh upon testing. Claims such as exceptional performance specifications in this case and big bargain may be indicative of a low quality or counterfeit product.

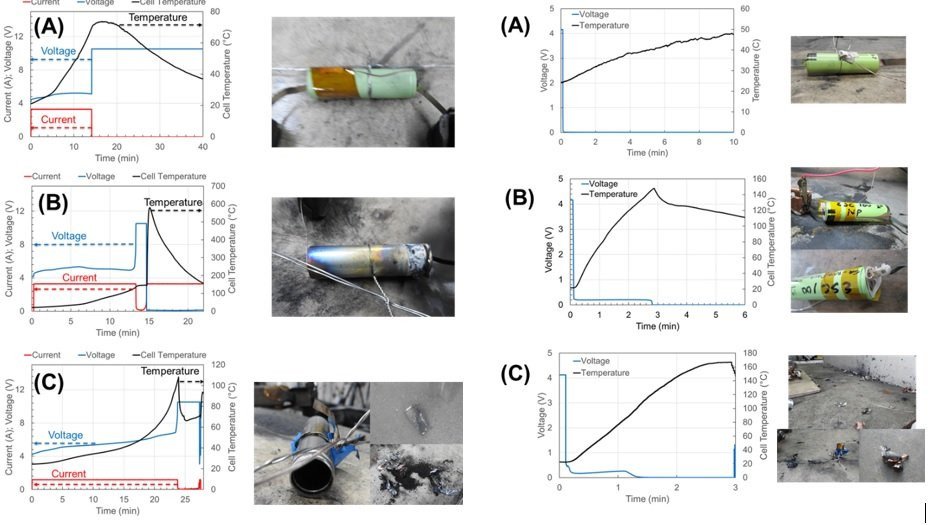

High-quality performance must be combined with safety to ensure reliable operation for any application using Li-ion cells. Built-in safety mechanisms at the cell level, as discussed earlier, prevent large damages arising from off-nominal conditions in cells during operation or storage. Cells from all three manufacturers were charged at 1C with a cutoff set at 12 V (Figure 8-left). This test demonstrates the effectiveness of cell safety features and protections offered by CID against overcharge conditions. When a cell is charged beyond its manufacturer-recommended voltage limit, the capability of the anode to accommodate Li-ion ions is exceeded leading to deposition of lithium metal on its surface and a reduction in thermal stability. Cells with CID offer protection against overcharge as in the case of cells from manufacturer A. The increase in the internal pressure of the cell activates the CID and breaks the internal connection to the electrodes, thus preventing further overcharge and keeps the cell from going into a thermal runaway. In cases of cells from manufacturers B and C in Figure 8, without the protection available from the CID, the cells continue to heat with a breakdown in the thermal stability of the cells. The overheating led to thermal runaway in cells from manufacturers B and C. Figure 8 shows a comparison of the post-overcharge test for cells from the different manufacturers. The accompanying post-test pictures for cells from manufacturers A, B, and C show the damages to the cells from the overcharge tests. High-quality cells from a reputable manufacturer prevent hazards such as extreme heating, electrolyte leakage, fire, and thermal runway under off-nominal conditions as observed in the cells from manufacturer A. Lack of protection typically offered by the CID renders cells from manufacturers B and C prone to these hazards. Electrolyte leakage, overheating, fire, and thermal runaway were observed for cells from manufacturer B. Thermal runaway with ejection of jellyroll was observed for cells from manufacturer C.

Another off-nominal condition that may arise in cells is short circuits that occur due to the inadvertent contact of the opposite terminals. Figure 8 (right) compares fully charged cells from manufacturers A, B, and C by applying an external short of 10 mΩ across the cells. The cell voltage drops immediately and the current reaches the maximum value with the application of external short followed by a stabilization period. Cell temperature continues to rise and may lead to uneven or localized heating in cells. Cells with PTC devices in the header as in the case of cells from manufacturer A offer protection in such scenarios by limiting the flow of current through the cell by increasing the resistance of the PTC device. Without such protection, the high heat sustained in the cell can cause overheating, venting with smoke, the release of hot liquid electrolyte, and cell rupture as observed in the case of cells from manufacturer B. In worst-case scenarios, the explosion of the cell and ejection of jellyroll may occur as evidenced in the case of cells from manufacturer C. The post-test pictures in Figure 8 show the results from external short tests.

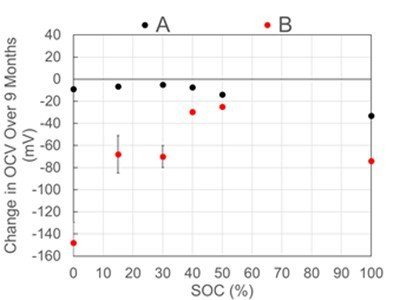

Superior charge retention and lack of memory effect make Li-ion chemistry favorable for many applications in addition to their high energy densities as well as long cycle and calendar life. Figure 9 shows the comparison of charge retention in cells from manufacturers A and B over a period of 9 months. Cells were charged to different states of charge (SOC) and stored at room temperature and the changes in open-circuit voltage (OCV) of the cells during storage were monitored. When comparing the results from manufacturers A and B, the drop in OCV is higher across all SOCs for manufacturer B compared to manufacturer A. In addition to this, the quality differences within a single lot of cells purchased also yield variable results at the same SOC for manufacturer B.

Devices powered by Li-ion rely on the proven performance, safety, and reliability of the batteries. Stringent quality control in the production of cells and batteries that power these devices is of utmost importance to ensure optimal and safe operation. Counterfeit products may forego some of the strict quality control measures needed to keep costs low. Furthermore, the lack of manufacturing know-how and resources needed for high-quality manufacturing may also affect the final product. Additional cost-cutting measures such as the use of cheap materials and lack of scientific and engineering expertise also yield low-quality cells.

Counterfeit products affect the overall performance and safety of battery-powered devices and appliances. Battery management systems (BMS) embedded within the batteries are expected to ensure normal operation and safety. Compromises in cell quality may affect the uniformity of the cells inside a battery pack making the BMS functions complex or inoperable. In some cases, the components that are used in the BMS may not be compatible with the charger or the battery design.

Transportation of Li-ion cells & batteries

Lithium batteries have been identified as a Class 9 dangerous good, during transport. To be safely transported (by air, sea, rail, or roadways), they must meet the provisions laid out in the UN 38.3 Standard for the Transportation of Dangerous Goods. This standard applies to batteries transported either on their own or installed in a device (UN codes 3090/3091 for lithium, 3480/3481 for Li-ion). And it applies to all points in the battery's transportation process: from sub-suppliers to the end-product manufacturer; manufacturer to the distributor; in or out of the product; in the field; during product returns or with non-original packaging. UN 38.3 has been adopted by regulators and competent authorities around the world, thus making it a requirement for global market access. The protocol includes identifying and classifying lithium batteries; testing and qualification requirements; design guidance and conditions and packaging and shipping regulations.

Counterfeit Li-ion products can be mislabeled or transported as undeclared shipments to avoid the restrictions. Events such as drops and impacts during transportation may cause cells to undergo venting, thermal runaway, and fire if they have not been tested and proven against such incidents as part of the testing and certification process. Due to the inferior quality of the products, they may also be prone to catastrophic internal shorts during the transportation process. Shipping counterfeit Li-ion products is a serious risk that causes accidents. Incidents of fatal crashes in cars and fires in airplanes have been reported to be caused by fire resulting from undeclared Li-ion products during transport.

Detecting counterfeit Li-ion cells & batteries

Counterfeit products may be difficult to distinguish from authentic and high-quality products. However, the following guidelines may be useful in detecting counterfeit products:

1. Visual inspection to look for signs of poor quality such as – inaccurate printing, misspelled wording, crooked label placement, and signs of defective workmanship.

2. After procurement of cells, measuring the cell voltage, weight, dimensions, and quality of the materials and comparing with datasheets available through original manufacturers may be useful.

3. Recognizing inappropriate or fake certification labels on the cells and batteries.

4. Being vigilant of significantly reduced prices in comparison with similar authentic products.

5. Quick delivery of procurement. Cells from OEMs typically take 6 weeks to 2 months to procure.

Considerations for Avoiding Counterfeit Products

Precautions must be taken during purchase to avoid counterfeit products. Some easy-to-follow considerations may help avoid these:

1. Purchase only from the OEM or from reputable retailers and suppliers recommended by the OEM.

2. Check every detail of the product as described in the previous section to detect and avoid counterfeit products.

3. Whenever possible, ask the vendor for pictures of the actual products. Compare the trademark and the logo with the authentic one.

4. Verify that the certification label is authentic.