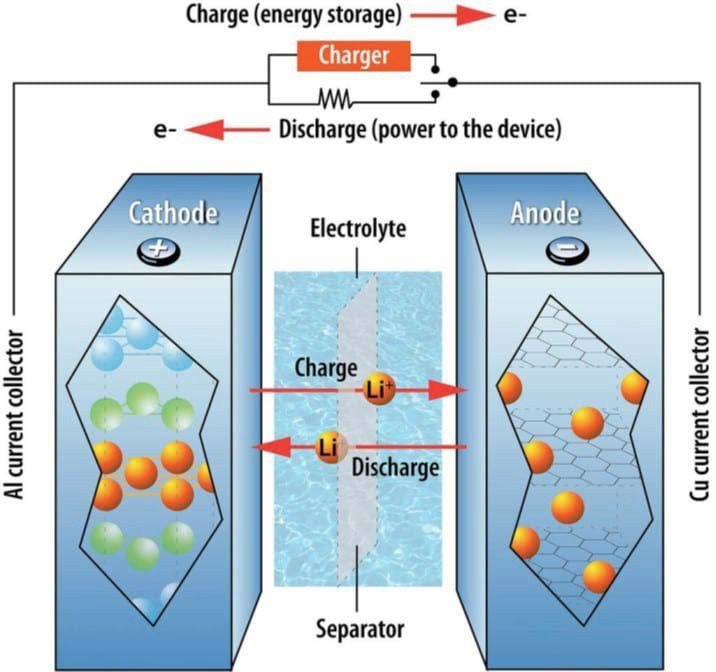

Electrolyte – Enabling ions transport within a Li-ion battery

Electrolytes are vital components of an electrochemical energy storage device. They are usually composed of a solvent or mixture of solvents and a salt or a mixture of salts which provide the appropriate environment for ionic conduction.

As per one of the industry reports, the global battery electrolyte market is anticipated to grow at a CAGR of more than 7.4 percent from 2020 to 2025.

Factors such as snowballing awareness level of cleaner transportation systems and the electric vehicle deployment are growing at a rapid pace globally, which in turn is estimated to create a huge demand for batteries, thereby providing a huge impetus to the battery electrolyte market.

Electrolyte material in Li-ion battery:

Electrolyte plays a key role in transferring the positive lithium ions between the cathode and anode. The most commonly used electrolyte is comprised of lithium salt, such as LiPF6 in an organic solution.

The electrolyte is characteristically a mixture of organic carbonates such as ethylene carbonate or diethyl carbonate containing complexes of lithium ions. These non-aqueous electrolytes generally use non-coordinating anion salts such as lithium hexafluorophosphate (LiPF6), lithium hexafluoroarsenate monohydrate (LiAsF6), lithium perchlorate (LiClO4), lithium tetrafluoroborate (LiBF4), and lithium triflate (LiCF3SO3).

Electrolytes are vital components of an electrochemical energy storage device. They are usually composed of a solvent or mixture of solvents and a salt or a mixture of salts which provide the appropriate environment for ionic conduction.

Battery electrolytes shuttle lithium ions between the positive and negative electrodes during charging and discharging. Most lithium-ion batteries use a liquid electrolyte that can combust if the battery is punctured or short-circuited. Solid electrolytes, on the other hand, rarely catch fire and are potentially more efficient.

In Li-ion batteries and capacitors, the key requirements linked with the electrolyte comprise:

- high ionic conductivity

- inertness towards the various species that may be present at the stage of assembly and/or resultant from the electrochemical or side reactions, thus ensuring low or no emissions of pollutant species

- reasonably low cost

- being able to stand a relatively wide temperature range warranting safety

- chemical and electrochemical stability

Solid and liquid electrolyte

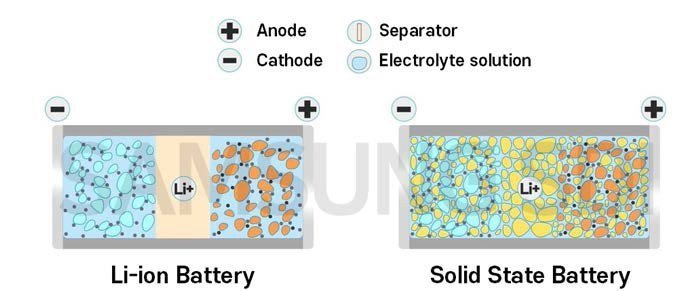

In a Li-ion battery used in smartphones, power tools and EVs use a liquid electrolyte solution. On the other hand, a solid-state battery uses solid electrolytes, not liquid.

At present, the commercially used Li-ion batteries have a separator that keeps cathode and anode apart, with a liquid electrolyte solution. On the other hand, the solid-state battery uses solid electrolyte, not liquid electrolyte solution, and the solid electrolyte plays a role of a separator as well.

Recent advances in the battery have resulted in rising of solid-state battery with solid electrolyte as it shows improved stability with a solid structure and increased safety since it maintains the form even if the electrolyte is damaged – which sometimes happens in Li-ion batteries. The current Li-ion battery runs the risk of battery damage such as swelling due to change in temperature, or leakage caused by external force since it uses liquid electrolyte solution.

Solid-state batteries also help to increase the capacity of EV batteries. Since a solid-state battery has a higher energy density than a Li-ion battery (which uses liquid electrolyte solution), it doesn't have a risk of explosion or fire, so there is no need to have components for safety, thus saving more space. In that space, manufacturers can add more active materials thereby increasing battery capacity.

A solid-state battery can increase energy density per unit area since only a small number of batteries are needed. For that reason, a solid-state battery is perfect to make an EV battery system of module and pack, which needs a high capacity

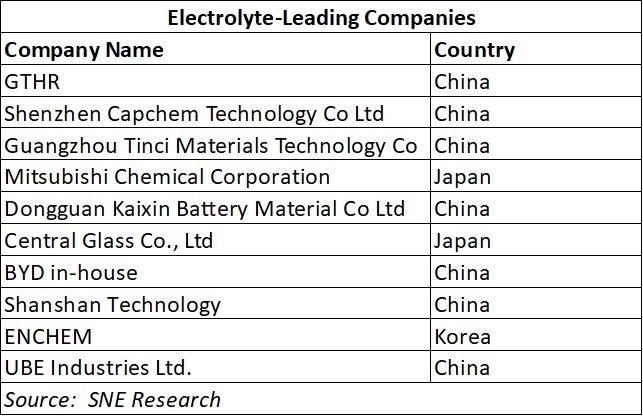

Leading companies in segment

To learn more about the electrolyte market development, ETN spoke to a few of the industry manufacturers who are leading in the segment:

Sumin Zhu, Ph.D., Co-Founder and CEO, Ampcera Inc.

Electrolyte offerings for the industry:

Ampcera offers the following commercialized solid-state electrolytes:

- Garnet-based LLZO oxide materials

- Sulphide-based materials such as Argyrodite, LPS, LGPS, LSPS, etc., LAGP and LATP NASICON-structure materials.

In addition, Ampcera also provides customized and proprietary solid-state electrolyte products to its customers and strategic partners.

Technology R&D for electrolyte materials:

Ampcera is focusing on solid-state electrolytes. The technology portfolio includes three areas:

- Materials

- Manufacturing technology,

- Applications in solid-state batteries.

Market share in the industry:

Ampcera is at present the global market leader for solid-state electrolyte materials with the highest number of customers. The market share is estimated to be at least 60 percent if not higher.

R&D strategy for enhancing electrolyte materials:

Ampcera focuses its R&D work on optimizing the performance of its solid-state electrolyte materials as well as developing scalable and low-cost manufacturing technology for integration in batteries to achieve a 450 Wh/kg energy density and a $75/kWh cost target.

The company has a roadmap to scale up its solid-state electrolyte materials production using its revolutionary engineering solutions.

Importance of high-performance electrolyte materials in solid-state batteries:

The solid-state battery is broadly considered as the next-generation lithium battery technology to provide significantly higher energy density, better safety, and lower cost than conventional lithium-ion batteries.

The key component in a solid-state battery is the solid-state electrolyte, which replaces the liquid electrolyte used in conventional lithium-ion batteries. High-performance and low-cost solid-state electrolyte materials are critical to achieving the benefits of solid-state batteries.

Development plans for the electrolyte market:

Ampcera will continue to collaborate with its customers and strategic partners to develop solid-state electrolyte materials and manufacturing technology for the accelerated development and commercialization of solid-state batteries.

The electric vehicle battery market is the main driver for the development of solid-state batteries and solid-state electrolytes. Ampcera is committed to the development and commercialization of our products and technology through both direct sales and licensing of our intellectual properties.

MU Ionic Solutions Corporation (MUIS)

Electrolyte offerings for the industry:

MU Ionic Solutions Corporation (MUIS) was founded in October 2020, as a joint venture company between Mitsubishi Chemical Corporation and Ube Industries, Ltd., and engaged in the business of electrolytes for lithium-ion batteries.

The electrolyte offerings are predominantly used for lithium-ion batteries, as well as lithium primary batteries, aluminium electrolytic capacitors, etc.

Technology R&D for electrolyte materials:

The electrolyte can greatly improve battery performance, including power output and lifetime, with functional additives tailored to the purpose, such as electrode interface control and prevention of overcharging (improving safety).

Market share in the industry:

MU Ionic Solutions Corporation has been one of the key players in the market and has a high market share particularly for batteries for xEV.

R&D strategy for enhancing electrolyte materials:

The company had been actively engaged in determining the differentiation of additives which has become a source of technological power because various functions can be added by the additives to be blended.

Importance of high-performance electrolyte materials in Li-ion batteries:

Electrolytes are ionic conductive solutions that are important components for smoothly charging and discharging lithium-ion batteries and for suppressing battery degradation.

Development plans for the electrolyte market:

The company aims to optimized solutions to meet customers' requirements such as high power, high safety, high voltage, and high durability through developing functional materials like additives.