BMW forms closed loop for recycling Ni, Li and Co from Eol batteries in China

The BMW Group is massively expanding its use of secondary material in closed recycling loops to achieve climate neutrality and sustainability. For the first time in China, the BMW Brilliance Automotive joint venture (BBA) has established a closed loop for reuse of the raw materials nickel, lithium and cobalt from high-voltage batteries that are no longer suitable for use in electric vehicles.

To realise this, BBA is working with a local recycler that dismantles retired batteries and uses innovative technology to recover a high percentage of the raw materials nickel, lithium and cobalt from the battery cells. The raw materials obtained in this way are then used in production of new battery cells for the BMW Group.

The company claims that the closed-loop material cycle conserves resources and reduces CO2 emissions by 70 percent, compared to using newly extracted primary material. BMW is already using secondary nickel in the high-voltage batteries of the BMW iX.

Jochen Goller, head of BMW Group Region China, says, "In light of the growing scarcity of finite resources and rising commodity prices, it is especially important to push forward with the circular economy, increase the percentage of reusable materials and reduce our dependence on raw materials".

The BMW Group will expand its recycling concept in China in the future, which will not only contribute to environmental protection, but also effectively support China's transition to a low-CO2 economy, he adds.

Being the world's largest market for EVs, China's automotive battery recycling industry has also experienced fast growth in recent times. The China Automotive Technology and Research Centre expects the total volume of retired batteries in China to reach around 780,000 tonnes by 2025.

The country's current policies require a high-voltage battery tracing system to be established to ensure batteries can be tracked and recycled once retired. The BMW Group has developed a system for this, with coding that enables seamless traceability of batteries throughout their lifecycle. The coding ensures batteries from the entire value chain, from initial test vehicles to vehicles already in the market, can be professionally recycled.

Once returned, the batteries are evaluated for potential continued use. According to the Group, it began using end-of-life batteries with a high residual capacity in forklift trucks at BBA plants in China back in 2020. The plan is for these "second-life applications" for batteries to be expanded, going forward, to include pallet lifting trucks and stationary energy storage units with charging capabilities.

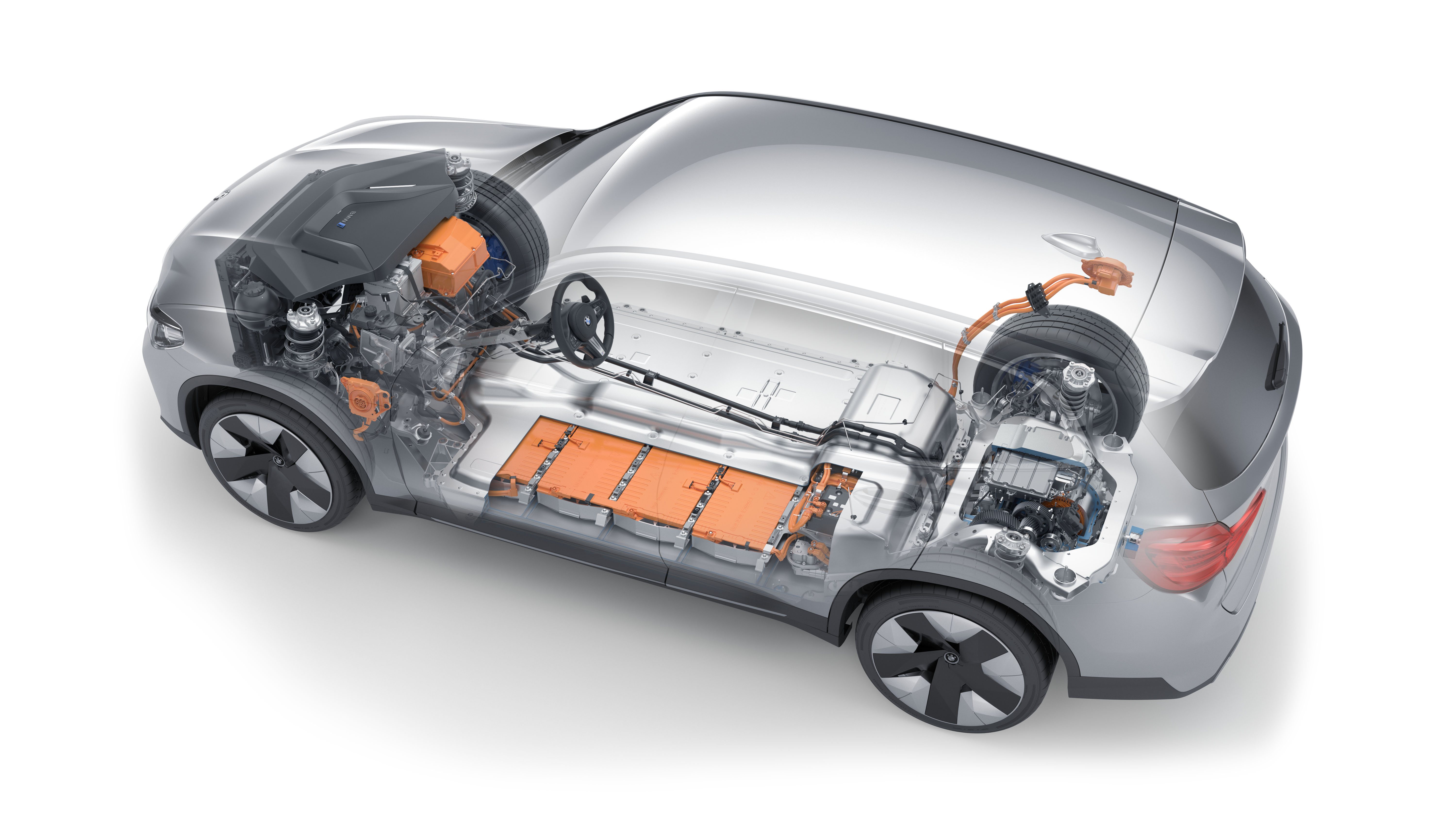

If end-of-life batteries do not meet the criteria for second use, they are recycled. A battery with a capacity of 100 kWh contains, on average, almost 90 kg of nickel, lithium and cobalt, with nickel accounting for most of this amount, it adds.