IESA decade: Building a credible energy storage community

Set up in 2012, the India Energy Storage Alliance (IESA) celebrates 10 fruitful years, this year on 3rd May. Having had a humble beginning with just five members, the alliance has grown to be an industry body to reckon with. Right from recommending inputs to shaping policy decisions, to promoting storage technologies through programs and driving customer awareness initiatives, IESA is working hard to build strong energy storage and EV ecosystem in India. Dr. Rahul Walawalkar, Founder & President of IESA, speaks about the challenges and efforts in the making.

What was the idea behind setting up an energy storage alliance? Why did you feel the need?

I started my work in energy storage in 2004 in the US, and in the first-ever project I worked on - where we looked at the role of energy storage in electricity markets - I got an opportunity to present the results at the US Energy Storage Association's (ESA) annual conference in 2005. I was very new to the field then, but the supportive environment provided by the ESA made a very big impact. In 2009, I got elected to the board of directors of the ESA and got deeply involved in how the US alliance was involved in promoting policies for removing barriers to energy storage technologies in the US market, and saw that with the involvement of the ESA the entire process became more effective.

When I moved to India in 2010, I realized that India had possibly bigger opportunities for energy storage adoption. At the same time, on the regulatory and policy side there was no awareness of the pace at which energy storage technologies were evolving. With my experience in the US, I realized that in India no company could individually take on the lion's share of the work for policy advocacy. The only way I saw this happening was by creating an industry alliance and starting pushing for policies for enabling energy storage and EV adoption in India. With this thought in mind, the India Energy Storage Alliance (IESA) was formed in 2012.

What was the role envisaged for IESA when you began, and how has it evolved over the years?

Originally, we began with just five member companies in the alliance. We started with a modest goal of creating awareness about advanced energy storage technologies so that India can adopt these technologies for reducing diesel consumption and making up an efficient energy market in India.

We were looking at energy storage both from stationary as well as e-mobility aspects. In the next two to three years, especially in 2014 after the new government came to the power, the national solar targets were scaled to 100 GW for 2022 from the original target of 20GW. Although the government has launched the 'Make in India' initiative, the focus of solar policy was primarily on price reduction through reverse auctions; so, the Indian market got flooded with imports from China for solar technology.

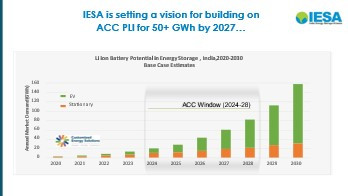

We realized we cannot let that happen with energy storage and replace dependence on oil from the middle east, with dependence on imported batteries from China. If we just focus on market creation and not on creating policies for enabling manufacturing and R&D, then we would see a repeat of what happened in the solar area where India would have been just flooded with imported solutions. So that's when in 2016, we started working on developing policies for enabling domestic manufacturing for advanced energy storage technologies. We are happy that, especially in the last five years, those efforts have resulted in the creation of the production incentive program for setting up 50GWh advanced chemistry cell manufacturing in India.

Of all the achievements that IESA has got in 10 years, which one are you particularly proud of, and why?

IESA has worked in many different areas, including microgrids for energy access, e-mobility, stationary energy storage, renewable integration, and manufacturing. I would say that the biggest achievement is the way we have built the IESA community; with more than 150 members now it spans all forms of stakeholders right from energy storage companies; to supply chain companies that are supplying components or processed chemicals for Giga factories, to some of the largest independent power producers leading the path for adoption of energy storage technologies in India. We also have research universities, national R&D laboratories as well as e-mobility companies right from startups like Ather to large automotive companies like Tata Autocomp and Toyota.

I feel that the best achievement is that we have built credibility around the kind of policy advocacy we have attempted over the last 10 years and that we have been able to bring together this diverse group of stakeholders. We have constituted vigorous best practices such as the creation of working groups for policy, technology, business as well as supply chain issues, where stakeholders regularly participate and share their views. That's what makes IESA a very effective forum for providing input to various stakeholders.

Tell us about IESA's involvement in policy decisions concerning the ES sector.

This is an area where my training at Carnegie Mellon University's Department of Engineering and Public Policy has helped me quite a lot, in terms of understanding what type of analysis is required for supporting policymakers. Policymakers get daily requests from different interest groups for policy support; they have to do a proper evaluation and benefit-cost analysis to determine which policy they are going to stand by.

At IESA, we have tried to focus on doing many of those analyses upfront, before we go to the government agencies, and that's where building a strong community is instrumental because it is difficult for any one company to achieve or understand all these aspects in depth. So, IESA working groups meet every Tuesday of the month for one hour, where typically anywhere from 20 to 40 IESA member companies participate to highlight issues/challenges and share their views. All analytical work is done by the IESA team beforehand and presented to the members at the meeting. All recommendations made at the meeting are compiled and presented to the IESA Leadership Council, which takes a final decision in terms of the position IESA as an alliance needs to take for addressing any concerns or opportunities that are available.

By following this rigorous process, the Alliance can identify many of the critical aspects of policy issues upfront, and by relying on all the members, we are also able to identify the right agency on the government side where we need to raise these issues. Over the last 10 years, we have been able to build strong credentials and credibility, such that policymakers and government agencies do invite IESA for sharing its views.

Apart from supporting the government in preparing a conducive roadmap for the industry, what else is IESA doing to promote the ES sector?

Other than the working groups we have created, we also hold various stakeholder discussions, where sometimes even non-members are invited, to try to understand their views. In the last 1-2 years we have conducted a series of roundtables related to Fire and Safety of lithium-ion batteries, battery swapping, and ACC PLI.

IESA has also taken various steps for connecting industry members with customers. For example, back in 2018, we started an initiative called 'E$ Meet', through which we conducted dedicated workshops in tier 2 and tier 3 cities where commercial and industrial customers are facing problems with power quality and reliability. We were able to bring together 50-60 serious customers in each location, who were struggling to find a solution, by partnering with local industry associations to address those issues and present innovative solutions and case studies provided by various IESA members.

Another aspect IESA works on is the annual conference, which has become a very important event for most stakeholders. IESA started hosting the annual conference back in December 2013, under the brand name 'Energy Storage India' in partnership with Messe Duesseldorf from Germany. Six such international conferences were held under the contract with Messe Duesseldorf, after which IESA started hosting the 'India Energy Storage Week' (IESW) in 2019. IESW has become an important event for most of the industry stakeholders, where they come together to discuss ideas or launch products, or take the industry forward. During this week we also host the 'IESA Excellence Awards', with this year being the fifth. IESA awards are independent and neutral, and not just restricted to members. Selection is based on merit and industry excellence is the only criterion.

IESA is one of the founding members of the Global Energy Storage Alliance which was created in 2014 to advance energy storage and e-mobility. In 2017, the global alliance launched the 'World Energy Storage Day' (WESD), to be held each year on September 22 (the autumnal equinox) to symbolize the role of energy storage in balancing the grid as well as balancing emissions from transportation. IESA has been hosting the global WESD conference for the last 3 years and it has the become a great platform with over 30 national and international partners (such as NITI Aayog, World Bank, IRENA, US Department of Energy, World Hydrogen Council, and many more) and unique event which sees participants from more than 120 countries over the 24-hour marathon event. Close to 200 speakers from 35 countries participated in last year's events and we're looking forward to building on this and making it a solid platform for bringing the global community together for celebrating advances in ES, e-mobility, and the green hydrogen industry.

In the growth of the energy storage use over the past decade globally, there have been spurts and plateaus, but now there seems to be a steady incline… where does India stand in this scenario?

If you look at both e-mobility and stationary storage, India is still in its infancy. We have lots of potentials, but we are in the very early days of scaling up both e-mobility as well as stationary storage deployments. In India, because of some of the legacy issues with the grid quality and reliability, there is a very strong adoption of advanced energy storage technologies for BTM applications like telecom towers or data centers or commercial and industrial customers. But with grid-scale energy storage, which has been in the limelight in many of the developed countries, in India we are just at the starting stage.

In the last five years, we have done a series of pilots, but now many large-scale RFPs are coming out from agencies such as NTPC, Solar Energy Corporation of India, and many others. We are expecting GWh scale energy storage deployment to start happening in the next 12 to 18 months.

Government subsidies and sops, and now the most talked-about PLI schemes to get India into the battery manufacturing race… it is an exciting time for the sector… how arduous is the run going to be?

It is going to be very challenging, I don't want to mince any words on that… because we are starting perhaps three years late. In 2016, IESA has set a vision to have 20 GWh of Giga factories in India from 2020-to 2022. The first set of Giga factories that are going to get operational in India will be some time at the end of 2023 or early 2024, but many of the 10+ GWh scales factories will only get commissioned in 2025 and beyond. So, we are at least five years behind regions like Europe and US, and more than 10 or 15 years behind China and Korea who have been leading the Giga factory deployments around the globe for the past decade.

There is no doubt that this is a very exciting time and we are looking forward to it, at the same time next 18 to 24 months are going to be extremely crucial and we need to put a very solid foundation for this industry. We need to put a lot of effort into scaling up the skill development and training efforts, particularly around the manufacturing processes, where there is very little work right now happening in India. We have to have a very steep learning curve.

Finding the right skill and talent is going to be very challenging and that's why IESA has launched efforts for the 'IESA Academy'. We are working with some of the international agencies including the US Department of Energy and various National Labs in the US to try to figure out how as part of the India-US collaboration we can bring attention to this area.

Government subsidy under the production linked incentives program will help tremendously, especially in the initial years of setting up Giga factories, to make sure that India-based manufacturers can compete with the global imports. At the same time, to become a global hub and to be competitive in the international market we have the next five years as time available to us, within which we have to get our act together.

Tell is about the recently launched India battery manufacturing and supply chain council.

The ACC PLI scheme is an incentive program meant for companies setting up Giga factories, and it is expected that these companies will have a target of reaching a minimum of 60 percent (many of the companies have proposed 70 to 80 percent) domestic value addition, which they will achieve within next five years. But there is no direct incentive available for setting up any of the supply chain activities in India, and that's where there will be a chicken and egg situation. When the Giga factories in India start procurement and try to achieve the domestic value chain, the factories are expected to get incentives but if you wait for that then it will be very difficult for the Giga factories to meet the stringent 3- to 5-year timeline for achieving the 60 percent domestic value addition target set by NITI Aayog and Department of Heavy Industries.

So, we decided to take this up as a challenge and the 'India Battery Manufacturing & Supply Chain Council' (IBMSCC) was set up under the IESA umbrella in December 2021. The effort will bring together more than 20 companies that are right now interested in setting up the various raw material processing industries, which can become a key part of the Giga factory supply chain.

Through IBMSCC we are trying to understand the requirements of the supply chain industries. We will also be undertaking a series of discussions with both, the State as well as Central government agencies to make sure that we can develop a robust supply chain, not just for the Indian Giga factories, but scale it up to become a potential global hub for supplying critical battery-grade materials to Giga factories around the world. They're a great window of opportunity available to India, because, after COVID-related issues, most the countries have realized that they cannot have a single source dependency for critical materials. Many countries are looking for alternatives to China, which currently dominates almost 80-85 percent of the supply chain for advanced battery chemistry manufacturing.

Are India's energy transition commitments too ambitious? What according to you is the reality check?

Many policy experts feel that India should not have accepted the deadline of 2070, but I'm an optimist. I believe that 2070 is a long way off, and the pace at which technology changes are happening if we can ensure that we are providing the right policy environment, remove barriers, and also address some of the issues related to financing, I think we could reach net-zero even before the target. I am happy to say that IESA is part of a 30-member expert committee appointed by NITI Aayog for getting inputs for India's net-zero energy transition.

Many countries are looking at moving towards net-zero by 2050, which means that most of the technology commercialization - even if they are in the early stages now - will happen in the next 10, 15, or 20 years. India will be able to leapfrog and will be able to adopt many of those innovations even before the target.

I think there was no legal or moral obligation on India to accept the target, considering currently India's contribution to the global greenhouse gas emission inventory is very small as compared to even China, or definitely as compared with other developed countries like the US and Europe. India could have asked for more time, but now that the ambitious target is set, I think it's up to the industry to try to see, how we take that as an opportunity and adopt many emerging technologies and achieve this target even possibly before 2070.

While the e-mobility sector will be the first to benefit from the 'Make in India' efforts, what is in store for stationary storage?

Our analysis suggests that for the next two or three years, stationary storage will be equally or even more important as a market driver for Giga factories, and then beyond 2025-26 e-mobility will start overtaking stationary storage.

Many times, I think analysts or experts underestimate the opportunity on the BTM site for the deployment of advanced energy storage technologies. In India, already more than 5 GWh of lithium-ion batteries have got deployed in the last 5 years on the customer side of the meter. These kinds of opportunities exist even right now and as these domestic manufacturing plants keep on coming up, I think some of these manufacturers will be focusing on their requirement of the stationary side as well.

On the e-mobility side, e-2W and e-3W are driving the adoption and it is expected that by 2025, the e-4W and the e-buses market will also grow. We expect the demand for batteries for EVs will be almost equally split 3 ways among them.

We see opportunities for stationery and e-mobility applications in India. One, sort of, dark horse right now is the large grid-scale projects and that's the area where the Indian government has announced a very strong target of reaching 500GW of non-fossil fuel generation by 2030. So, going from the current target of 100GW solar, they are looking at getting to at least around 300+ GW of solar by 2030 and having another 100-150GW of wind as part of it. There are a lot of opportunities on the stationary storage side as well, and some of the tenders (like the recently released 1GWh tender by SECI, the NTPC tender, etc.) will decide if the grid-scale energy storage requirements will also scale up very rapidly in India.

How do you see IESA grow in the coming decade?

I believe that the coming decade is going to be lots of fun for IESA, as a team, and as a community because many of the struggles that we had in terms of getting the right policies or convincing people about the sector are now done.

Many of the technologies today are getting commercialized, and now we need to focus on accelerating the adoption and making sure that we do not stumble because of safety issues like the recent 2W fires.

The priority for IESA in the coming decade will be on two fronts:

- -one is through initiatives like the 'EV Adopter Circle', where we are trying to make sure that we are not just talking about EV or energy storage 5 to 10 years down the line, but trying to identify customers in the next 12 months, who can adopt stationary energy storage as well as e-mobility economically and help them in achieving that, and set up examples so that next year even more customers can adopt these technologies.

- -the second is that IESA has set a goal of making India a global hub for R&D, manufacturing, and adoption. And for enabling that, I think skill development is going to be very crucial. That's where we are very heavily investing, in building the IESA academy as a platform, where more than 50 courses are available; there is a pool of 120 + industry and academic experts who have joined our expert panel and we will be focusing and introducing many industry-oriented training programs that will help industries in acquiring and filling the skill gap. We are thankful to partners like ARAI, Society for Automotive Engineers, Indian Electrical and Electronic Manufacturers Association, Pune University, UL, and other partners for helping us address this need for the industry.