24M launches direct-material recycling process for semi-solid Li-ion batteries

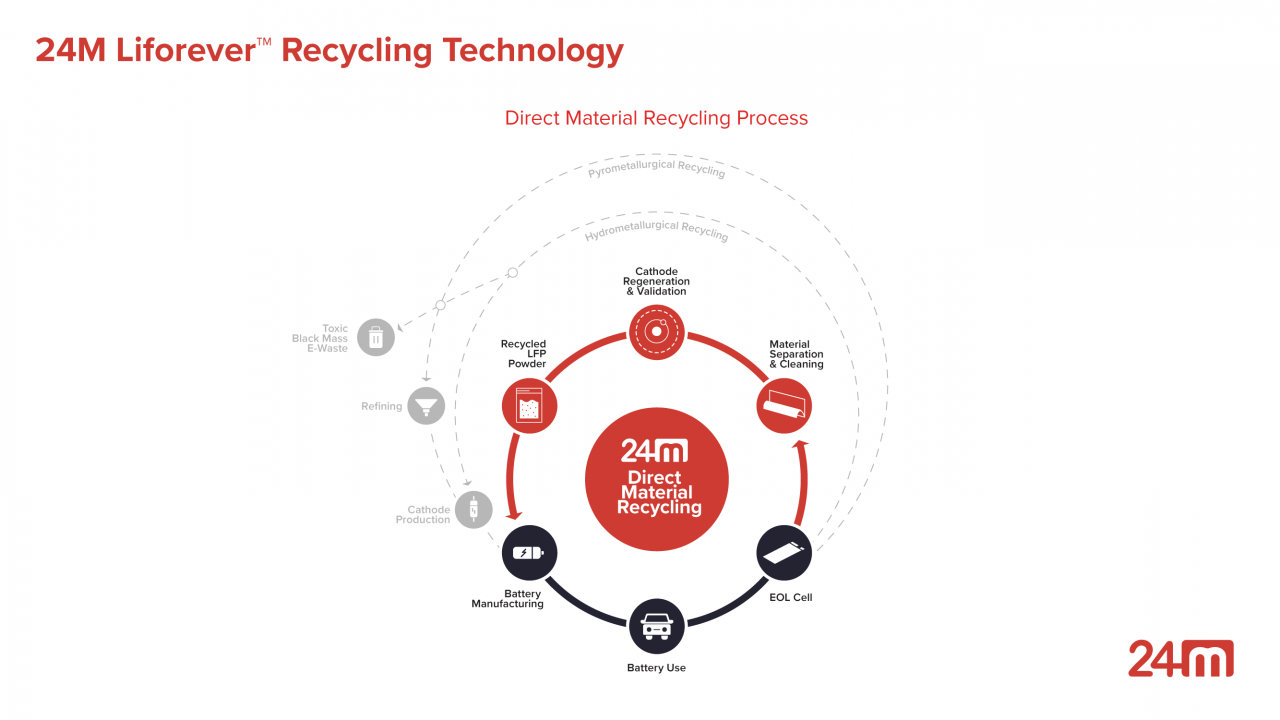

24M Technologies (24M), a Massachusetts-based battery technology firm has unveiled 'Liforever' – a direct material recycling process for semi-solid lithium-ion batteries for electric vehicles and energy storage system batteries.

The latest innovation is unique to the 24M semi-solid battery manufacturing platform and is said to reduce the environmental impact of lithium-ion batteries by enabling efficient and cost-effective recovery and reuse of battery materials, including lithium iron phosphate (LFP) both in the process and at end-of-life.

"Better battery recycling is essential for a sustainable energy future, but the use of binders in conventional cell production has made direct recycling impractical," said 24M CEO Naoki Ota.

"Liforever solves these challenges by enabling the reuse of nearly every part of the battery cell without requiring the expensive, inefficient, and environmentally challenging processes used in conventional cell recycling. These cost savings are further optimized by our streamlined semi-solid technology, which eliminates half of the steps used in conventional cell production."

Conventional lithium-ion cells use pyrometallurgical and hydrometallurgical recycling processes that form black mass e-waste, damaging the structure of anode and cathode materials, 24M stated. Owning to the damage and the high cost involved in these processes, less expensive materials like LFP are typically not recycled with the focus on extracting expensive metals like nickel, manganese, and cobalt from the black mass which are then reintroduced in the active material production process.

"By contrast, Liforever keeps the active materials in their original form and does not create a black mass — something no one else in the industry can do," 24M said in an official release.

This enables low-cost recycling of all active materials from the anode (graphite) and cathode (NMC, LFP, NCA, etc).

24M claims its recycling methodology is chemistry-agnostic and compatible with current and anticipated future recycling regulations, allowing cell manufacturers, EV OEMs, and ESS operators to future-proof their battery technology.