Battery fires heat up e-mobility adoption

The fire risk and hazard associated with high-energy battery storage have become a major safety concern for EV adoption. Runaway fire instances in different parts of the world have raised a burning concern over the safety of using EVs. Mitigation efforts, while challenging, are being made to ensure battery safety as the need of the hour.

The fledgling energy storage sector is just about experiencing a sunrise phase brought on by increasing deployments, marked by policy support, and decreasing battery costs. The prospects of battery storage applications are gathering momentum, especially with respect to EVs. At the same time, the industry is opening its eyes to the troubling fire accidents - mostly related to Li-ion batteries – that are a nagging concern and could pose a roadblock in the growing e-mobility adoption world over.

Over the years, the electric vehicle has considerably changed the car industry globally, driven by the fast development of Li-ion battery technology. As more and more people purchase EVs, there is growing anxiety about what happens if these vehicles catch fire.

Regardless of the undoubted benefits of electrifying our transport fleet – from reduced air pollution to facilitating the accomplishment of the necessary net-zero targets – there is a rising sense of concern in the EV community, over the dangers and evident spontaneity of EV fires. The fire risk and hazards associated with high-energy batteries have become a major safety concern for EVs.

Though the EV fire incidents aren't as common and frequent as those seen in gas or diesel-powered cars, the risk is very real; adding urgency to the development of enhanced safety standards.

Types of Li-ion batteries

All three types of lithium-ion batteries (LIB) currently used in electric cars - cylindrical, prismatic, and pouch-type - are the same in functionality, but each has its pros and cons. Cylindrical and prismatic batteries are cased in hard materials. Pouch-types use sealed flexible foils and are protected by thin metal bags.

The technology used in cylindrical batteries is old and yields consistent results. These cells can withstand high internal pressure without deforming. They are also cheaper, making them ideal for mass production. But they are heavier, and their shape stops cells from being packed as densely as with other battery forms. Tesla mostly uses cylindrical batteries, some supplied by LGES.

Prismatic batteries are deemed safer and lighter than cylindrical cells and, because they are rectangular, can be more closely packed. They optimize space better than cylindrical cells but are typically more expensive and have a shorter lifecycle. They also tend to swell.

Compared with cylindrical and prismatic cells, pouch-type battery cells allow for lighter and thinner cell fabrication and design flexibility for different capacities and space requirements for different vehicle models. However, they are vulnerable to swelling and pose a greater fire risk in a crash.

As with practically all technology, batteries have evolved a lot over time and yet the basics stay the same – you are dealing with high levels of energy in a concentrated mass.

EV battery thermal runaway

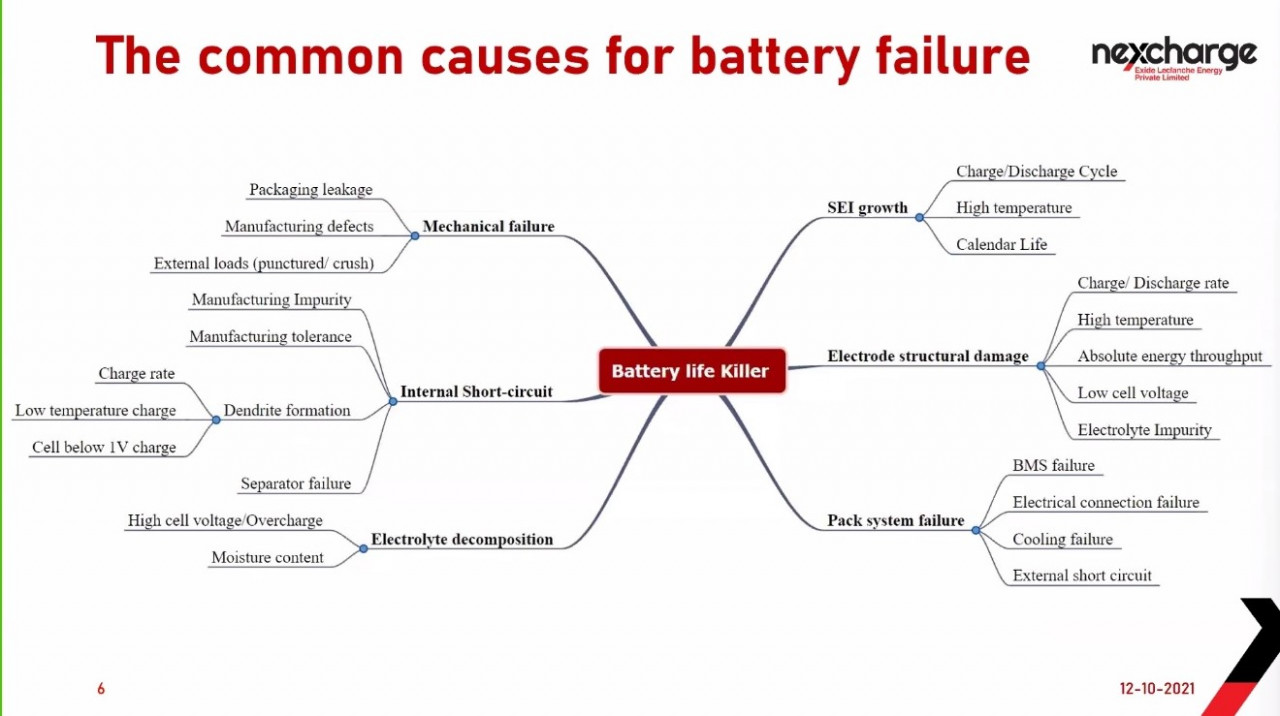

Thermal runaway, a rare but lethal failure mode in LIBs, happens when corrosion and reduction reactions in a deteriorating cell generate adequate heat to create a feedback cycle, generating high temperatures and gases. This condition eventually causes the cell to rupture, releasing hazardous, flammable gases into the atmosphere. As one cell vents, it pushes the next one to follow suit, creating a potentially explosive, cascading runaway situation.

Types of thermal runaway

- Electrical abuse (over-charging/discharging) - Overcharging or discharging to voltages beyond the manufacturers specified charge range could be responsible for lithium plating or dendrite formation on the anode. Later these dendrites may pierce the separator causing a short circuit between cathode and anode, leading to thermal runaway.

- Thermal abuse (over-temperature): Internal temperature of the cell in the 90-120o range will cause the SEI (solid electrolyte interphase) Layer within a Li-ion battery to decompose exothermically. At temperatures above 200o, the hydrocarbon (organic) electrolyte can decompose and release heat.

- Mechanical abuse (penetration, pinch, drop and bend): Mechanical abuse can result in electrical shorting between the electrodes, via the electrolyte, producing localized heating.

- Internal short circuit (ISC): An ISC occurs due to the failure of the separator, allowing contact between the cathode and anode via the electrolyte. This can happen due to any of the above three abuse conditions or because of a manufacturing defect.

Battery fire incidents in India

Battery-related safety hazards aren't unheard of in the global EV industry. They are becoming more common with the rise in volumes and increase in demand.

Considering the growing market size of electric scooters in India, three scooters catching fire is a matter of concern and requires some thought. The recent battery fire incident in e-scooters from Pure EV and Okinawa that has been viral on social media sites, has put a question on the safety expectations of the battery-operated vehicles as well adding to the apprehensions of customers to opt for an e-vehicle. The reason for such fire incidents is said to be the kind of batteries used within the vehicle.

EVs use larger and heavier LIBs. There is a risk of fire, although this only happens if the battery is either not manufactured correctly or is damaged. Also, the software that operates the battery may not have been appropriately designed.

It is significant to focus on EV battery safety, the hazards, and challenges, to better understand this emerging technology and work to advance safer energy storage systems globally.

Addressing EV battery safety

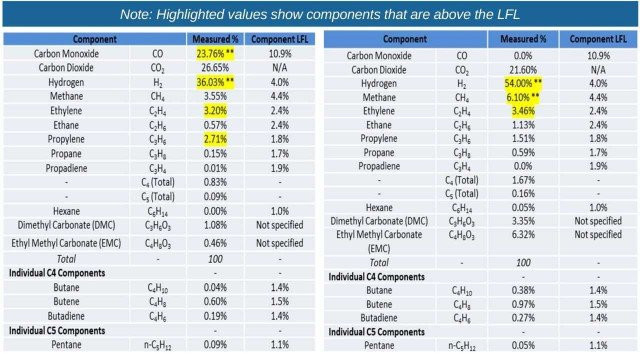

In one of the studies titled Fire and gas characterization for Li-ion cell and battery fires, UL demonstrated that toxic and flammable gases are released from Li-ion cells when they experience thermal runaway and fire. The level of toxicity and the combustible nature of the gases depends a lot on the volume in which they are released into and trapped. Hence, one should take the free volume of the location they are installed in to determine the toxicity and flammability of the released gases. The nature of the gaseous components depends significantly on the chemistry of the Li-ion cell as well as the composition of the electrolyte solvents and salts.

A good understanding of the gas composition is imperative for battery installations such as stationary grid ESS, or when vehicle battery charging is carried out in a poorly ventilated area, to provide the required information to first responders and firefighters.

Dr. Rahul Walawalkar, President - IESA, and MD - CES (India) said "With new technology getting sensationalized, on the EV front, there has been an improvement, and paying attention to safety issues is a must to avoid serious circumstances. There are enough growth opportunities to accelerate the e-mobility sector in India. We need to focus on the battery and related aspects that play an important role in ensuring the long-life of e-vehicles."

Dr. Tata Narsingha Rao, Director (Additional Charge) - International Advanced Research Centre of Powder Metallurgy & New Materials (ARCI) said "If you leave the battery idle for a long time and due to non-linear cells, they start self-discharging, then you are taking a battery pack that is already discharged and charging it. In such a case, a battery fire incident is bound to happen due to the cell's formation. People must be educated to handle EV fire situations. Safety awareness must be in place. The battery pack must be assembled intelligently. LFP batteries are a safe option; LTO batteries are a healthy option too for Indian conditions."

Stefan Louis, CEO, Exide Leclanche Energy Pvt. Ltd said "A Li-ion battery, the electrolyte that can catch fire is an organic liquid. We have found that thermal events can be predicted under the new Indian safety standard. In electric vehicles, one bad cell in a pack of millions of cells will harm the battery pack. The battery is complicated chemistry. The Li-ion cells are widely used in different applications. The role of BMS is external and cannot predict the internal happenings within the battery. The thermal event of the battery is a difficult task to get over."

There are best practices to ensure the quality of battery pack assembly and should be applied. Not every kind of battery is manufactured globally suitable for the Indian market. It is important to create a battery pack thermal safety rating over environment temperature, it will help in picking up the right battery.

Robust battery thermal management

EV batteries thermal performance and heat control are essential for the effective operation of all types of EVs in all climates and environments to maximize vehicle performance, thermal management of the batteries becomes very critical. The battery thermal management system (BTMS) has a crucial role in controlling the thermal behaviour of the batteries. Numerous cooling methods are used for battery thermal management systems such as air-cooling systems, liquid cooling systems, direct refrigerant cooling systems, phase change material cooling systems, and thermoelectric cooling as well as heating system.

Dr. Salahuddin Ahamad, Ph.D., Assistant Manager - Exicom Tele-Systems said "We aim to make robust thermal management system for the battery. The reaction inside the cell under a thermal management system is ample and such parameters should be considered while designing a robust thermal management system model. Thermal runaways are important to determine and ascertain a robust model in place. The experiments are in place."

Data-driven BMS

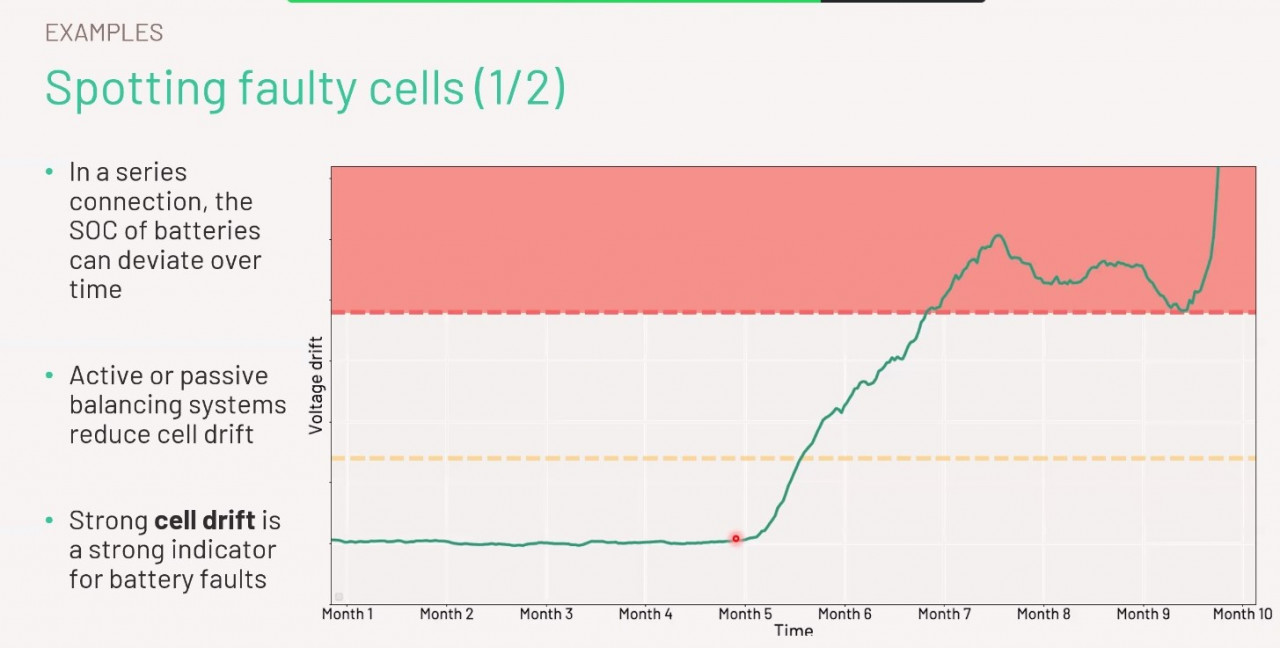

The main function of BMS is to guarantee that the battery is protected and any operation out of its safety limit is prevented. It monitors the battery pack's state of charge (SOC) along with the state of health. It also manages the battery optimization via cell balancing that improves the life of the battery in the long run. The BMS will also monitor voltage, different temperature parameters, and coolant flow.

To make informed decisions in an ever-accelerating battery world, companies need dependable data, from the electrochemical properties of batteries to their real-life behaviour in the field.

The ongoing trend towards even higher energy densities adds fuel to the fire. The relationship is quite simple: the more energy is stored within a single battery cell, the more energy is released in case of a failure.

Dr. Kai-Phillip Kairies, CEO - ACCURE Battery Intelligence said "Every BMS is generating some sort of data, and interpreting the same is quite a challenge as well as prone to errors. The BMS is meant to protect against external errors, and it can fail due to being faulty. One good indicator of battery health is the balancing of battery cells. The difference in voltages is a good indicator of the performance of the battery pack. There are few ways to detect faulty cells before they prove to be dangerous. The data collected must be leverage to keep a health check through intelligent data monitoring."

Identifying the right battery chemistry

The fire risk and hazards associated with high-energy batteries have become a major safety concern for EVs. Although the Li-ion battery market is relatively established with a robust supply chain, there are some anxieties associated with raw materials that make up the current LIB, and thus, there is a significant market appeal to battery chemistries beyond Li-ion.

Any alternative chemistry that can help prevail over limitations associated with the current Li-ion technology can revolutionize the e-mobility industry. Although it is relatively evident that EVs are going to be the way of the future, it remains to be seen which technologies and chemistries would drive to that future.

In Indian conditions, battery cooling is essential. We look at multiple battery chemistries which have long-term horizons in terms of safety. The highest adoption of e-mobility is in the e-bus segment in the country. The safe battery chemistries will accelerate EV adoption in the country.

Nishant Arya, Vice-Chairman - JBM Group said "We have to provide end-to-end solutions to the customers. Looking at the battery pack, we are looking at the safety of high-voltage batteries. The e-buses require a huge battery pack, so the best safety system has to be in place in terms of battery packs. The driving patterns for e-buses have to be enhanced multifold. The TCO has to be improved, and safety measures are important to guarantee the customers the long life of the vehicle."

Technology partnerships

India is one of the largest car markets in the world, but that market is on the brink of a transformation. The government of India is promoting e-mobility in a big way and the Department of Science and Technology (DST) is working towards technological solutions through R&D efforts with the industry and research laboratories, to realize the electric dream of 400 million customers by the year 2030.

The DST has joined hands with the Department of Heavy Industry (DHI) to establish a Technology Platform for Electric Mobility (TPEM), that will be funded primarily by the DHI, and the program management will be undertaken completely by DST.

Dr. Sajid Mubashir, Scientist G, (EV R&D Mission, EV Charging Standards) - Dept. Science & Technology (DST), GoI said "When I look at chemistries, basically NMC is an extension of LTO batteries. The variants which are not cobalt batteries have better charging ability. There is a need for a strong standards and regulations system. The cars in India are mostly small, so the transformation to e-mobility will come in this segment. It is a difficult market. So, we can look at a collaborative platform for getting technologies into the market. The Indian e-2W is an emerging and engineered market. We have been able to cover entire charging infrastructure standards for light vehicles."

Andy Back, Head of Engineering - Italvolt SpA said "The quality check is an important aspect of battery manufacturing. We have 3-5 years to keep the consumers ahead of the curve on the emerging e-mobility. There are interesting technologies transformations globally, on battery manufacturing. We believe in genuine partnership with customers and supply chain partners. The design of the cell must be considered for intelligent battery pack assembly. We must do things like standardization of charging systems, correct identification of firmware to prevent battery fire incidents. Battery manufacturing is an automotive process. There is need real data for developing and delivering efficient battery packs for e-vehicles."

LIBs are the power source of choice for various applications, EVs as well as stationary storage. But though the applications for LIBs may differ, the technology is similar, and hence so are the hazards.

All battery systems, irrespective of use, are built with safety mechanisms are at work and are meant to allay dangers. The systems use structural and mechanical ways to keep batteries cool and prevent thermal runaway. There are safety protocols and procedures that are known to the operators and manufacturers, like in any other energy system.

In the case of EVs, it is still a new domain, which makes the risks more pronounced even when the fire occurrences are one in millions. Even the conventional mode of transportation has similar vulnerabilities, but the safety measures are more known and adhered to. Perhaps, with time and adaptability, the risks can be controlled and mitigated, but till then the newbie sector is cautious of its run on the road.

Kannan Subramanian, Deputy General Manager-Electrification - Bosch Ltd said "It is important to understand that the global electrification journey is in its 2nd generation. Understanding the application for which the battery is being designed is important. Every application has different chemistry. It is important to take two steps back and think product development has to be specific to the application it is developed for. There is a trade-off situation in the industry and has to be taken into consideration for developing a reliable product."

The recent battery failure globally has been multi-point and accumulated over the period. The fundamental of battery is the choice of chemistry for the specific application. While adopting global standards, not all standards can be implemented in the Indian cost-sensitive market. So, there is a need to develop indigenous standards suitable to the Indian conditions.

Standards and certification

ARAI (Automotive Research Association of India) has geared itself to support the automotive industry for EV development, evaluation, and certification. Under the FAME project, ARAI has set up the comprehensive state-of-the-art Centre of Excellence (CoE) for EVs (2W, 3W, passenger cars, buses, and commercial vehicles) and their components such as traction batteries, motors, controllers, chargers, etc. This centre will support the government`s e-mobility mission to scale up EVs in India.

Anand Deshpande, Sr. Deputy Director & Head - Automotive Electronics Department, ARAI said "Considering the importance of battery safety, we are having a good set of standards in place in India in the lines of global standards to ensure battery safety for e-vehicles. At our lab, during the approval phase, the approach is a system-level approach. While we address the overall EV safety, we do look at battery safety. The standard focus is on electrical, thermal hazard management. Utmost care is taken on approving the battery for Indian conditions. User awareness is important for the charging and discharging process of the battery."

Tapping into the expertise in batteries, Underwriters Laboratories (UL) are developing UL Standards for large batteries and other onboard components. Since the late 1990s, UL has developed a series of UL Standards for EVs that meet the demands of the new energy era by utilizing the applicable UL Standards and existing EV standards.

Dr. Judy Jeevanraj, Vice President-Research - Electrochemical Safety Research Institute, Underwriters Laboratories Inc. said "Optimization of Li-ion batteries is still an ongoing process. The hazards can be classified into three categories. The different battery chemistries require different charge configurations. While designing the batteries, it is essential to make sure safety controls, the number of cells use in the module are in place. All cell voltages should be put in a band and then tie the band together in a specific manner. BMS (battery management system) is important. Active and passive balancing must be in place. The heating and cooling of the battery pack are essential and must be optimized at the cell level. The design and usage aspects must be optimized."

The energy storage industry is still in its infancy but constantly improving. Adapting as it grows - to user demands, technology trends, pitfalls, and upkeep; like with any other industry, it will continue to improve as it grows. Similarly, risk factors will have to be handled with enhanced standards and safety practices. Proper mitigation measures must form the core of the battery system design. And to implement risk-reducing factors, it is important that all stakeholders — manufacturers, operators, and first responders – all work together to better protocols and standards.

(To understand the different nuances of EV battery hazards, Emerging Technology News with the support of its partners organized a roundtable on Battery Fire! New Challenge towards E-mobility on October 12. The insightful comments on EV battery risks and mitigation, by the eminent speakers at the discussion have been incorporated in this article, lending it a voice of knowledge and experience.)