Clean Hydrogen Mission: Forging a united front to tackle climate change

About two-thirds of global emissions arise from transportation and hard-to-abate industries such as steel. Clean hydrogen serves as a promising solution for decarbonizing these sectors.

Green hydrogen holds immense promise as a clean energy solution. The fuel is derived from renewable sources through a process of electrolysis, the emission-free production process making it an attractive alternative to fossil fuels and a versatile energy carrier that can be used in various sectors from hard-to-abate industries and heating to long-distance transportation.

With its potential to reduce carbon emissions and contribute to a more sustainable energy landscape, green hydrogen is garnering significant attention globally and driving innovations in the quest for a greener future.

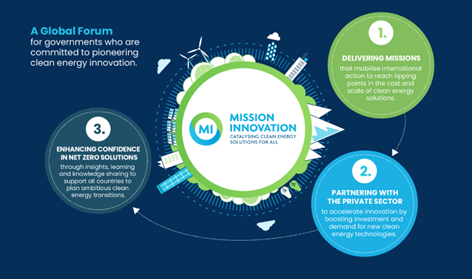

Mission Innovation

Mission Innovation (MI) is one such global initiative and aims to strengthen investments and accelerate actions in the global clean energy domain by spurring innovations that will make clean energy affordable, accessible, and attractive for all.

The action-oriented platform serves as a forum of 23 countries and the European Commission (on behalf of the European Union) across six continents working to deliver technologies capable of transforming sectors that are responsible for 50 percent of global emissions.

It was launched at the 21st Conference of the Parties (COP21) in November 2015 when world leaders committed to doubling their government and/ or state-directed clean energy research, development, and demonstration (RD&D) investments over the next five years.

MI brings together delivery-focused alliances between the public and private sectors, investors, and R&D institutions working to reach tipping points between the cost and scale of the technologies needed to accelerate decarbonization worldwide.

The missions under MI include: Zero Emission Shipping, Clean Hydrogen, Green Powered Future, Carbon Dioxide Removal, Urban Transitions, Net-Zero Industries and Integrated Biorefineries.

Clean Hydrogen Mission

Clean (meaning green) hydrogen is a vital part of the portfolio of solutions required for decarbonizing the global economy. However, cost remains the biggest barrier to its deployment and application. Currently, it is three times more expensive to produce clean hydrogen than hydrogen produced directly from fossil fuels.

To address this issue, on June 2, 2021, the Mission Innovation Clean Hydrogen Mission – a global coalition to support the development of the clean hydrogen economy – was launched at the 6th Mission Innovation (MI) ministerial meeting hosted by Chile.

The goal of the Clean Hydrogen Mission is to reduce the costs of clean hydrogen to the end user to $2/kg by 2030. The idea is to facilitate cost reduction across the value chain including production, handling, transportation, and storage. To achieve this, the mission will support both research and innovation and the development and delivery of at least 100 large-scale integrated "hydrogen valleys" worldwide.

To enable the $2/kg tipping point, the mission's activities are organized into three key pillars:

1. Stimulating Research, Development, and Innovation – Tackle top research and development priorities that have the greatest potential to bring down costs across the clean hydrogen value chain. Priority will be accorded to innovations that reduce production cost, support large-scale, low-cost hydrogen storage and compression technologies, and research and innovation in technologies used in hard-to-abate sectors.

2. Integration of Production, Storage, Distribution and End-use Applications in Hydrogen Valleys – The goal is to deliver 100 clean hydrogen valleys worldwide by 2030. To achieve this, MI will prioritize innovations that would enable successful demonstration of production, storage, distribution, and end-use in a defined geographic area and address barriers like funding, regulatory provisions, and certification standards.

3. Preparing the Ground for Scale-up of the Hydrogen Economy – The mission will foster international collaboration between governments, private sector, and other institutions to provide a clear, coherent, and enabling environment for the creation and scale-up of a hydrogen economy. The mission will also work towards creating codes, certifications, standards, and regulations for such an economy, similar to mechanisms underpinning the fossil-fuel-based market. It will encourage cross-cutting research in fields such as the environment, social license and safety, policy and regulation, and modeling (including techno-economic) across the whole hydrogen value chain to support the development of an enabling environment to accelerate the uptake of clean hydrogen.

Hydrogen Valleys

Hydrogen Valley refers to a geographical area – a city, a region, an island, or an industrial cluster – where several hydrogen applications are combined into an integrated hydrogen ecosystem. By co-locating producers, suppliers, and end-users of hydrogen, the hydrogen valleys help in achieving economies of scale through shared infrastructure, serving as concentrated demand centers, which in turn helps to reach critical scale and reduce end-to-end cost.

The Clean Hydrogen Mission is committed to facilitating the delivery of 100 such large-scale integrated hydrogen valleys by the end of the decade.

According to the Mission Innovation Clean Hydrogen Valley Platform, there are 87 planned/ announced hydrogen valley projects across 34 countries with a total investment of €152 billion. Of these valleys, seven are under construction and four are fully operational. The three fully operational hydrogen valleys are:

eFarm, Germany

The project includes five electrolysis sites near existing wind farms, two hydrogen refueling stations, two fuel cell buses, five production locations and 35 fuel cell cars with a total output of 1.125 MW. Interest has already been expressed for acquiring another approximately 100 vehicles. The waste heat generated at the electrolyzers is used to heat buildings.

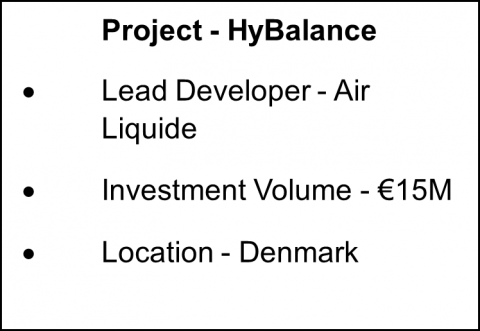

HyBalance, Denmark

The HyBalance project in Denmark, one of Europe's biggest and most advanced hydrogen facilities, was inaugurated in 2018. By September 2020, the facility had delivered 120 tonnes of hydrogen. The HyBalance project demonstrates the use of hydrogen in energy systems. Here, hydrogen is produced from water electrolysis, while also enabling the storage of renewable electricity generated from wind turbines. This balances the grid, and the hydrogen produced is used for transport and industrial use.

The facility was developed by Air Liquide, Hydrogenics, Ludwig-Bölkow-Systemtechnik, Centrica and Hydrogen Valley. The project received funding from the European funding authority FCH JU (Fuel Cell and Hydrogen Joint Undertaking) and Danish funding program EUDP (Energy Technology Development and Demonstration Program). The FCH JU funded the project to the tune of €8 million, while EUDP, which supports private companies and universities to develop and demonstrate new energy technologies, funded €2.6 million.

The Rugao Hydrogen Energy Town, China

The United Nations Development Programme (UNDP) - China Hydrogen Economy Pilot Rugao Project was officially launched in August 2016 to demonstrate low-cost, low-carbon hydrogen production, transportation, and applications as well as to generate knowledge and good practices from the pilot initiatives to ensure the sustainability of the project and establish a replicable model to be shared in other places in China.

The city, located in Rugao Economic and Technological Development Zone, Nantong, in East China's Jiangsu province, boasts a moderately complete industrial chain that involves the production, storage, and delivery of hydrogen, as well as the development and application of hydrogen fuel cells. According to the Nantong government website, the development zone is home to a 666,667 square meter hydrogen energy industrial park that is equipped with a hydrogen supply base and facilities customized for companies in the sector.The project is said to have 10 laboratories and is the only institution that is qualified to evaluate hydrogen fuel cells in the province and in the Yangtze River Delta region. Additionally, a total of 16 hydrogen fuel cell buses and 57 freight cars entered the market (as of June 2021). The first mobile communications base station powered by hydrogen fuel cells in Rugao has also been put into operation.According to data on the UNDP website, the procurement of the FCV testing equipment was done within 2021, however, delivery and test operations had to be postponed to Q1 2022; hydrogen and fuel cell vehicle operations and manufacturing in Rugao continued to be demonstrated throughout 2021. Due to various reasons, it was agreed that the project had to be extended to the end of 2022.

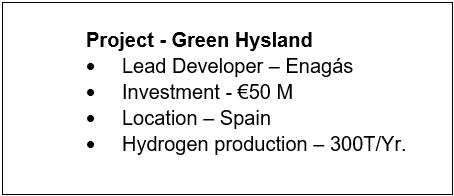

Green Hysland, Spain

The Green Hysland hydrogen valley project is a fully operational hydrogen valley in Spain that aims to create a replicable Hydrogen Territory in the Balearic Islands by converting solar energy generated in Mallorca into green hydrogen which can be used in multiple applications: mobility, heat, and power and for the gas grid.

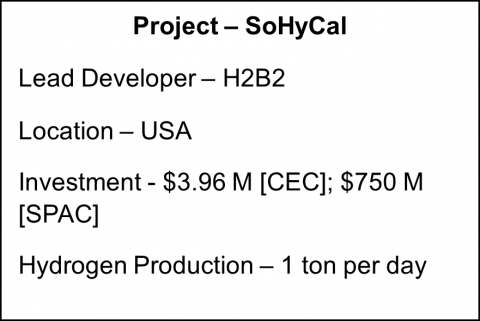

SoHyCal Facility

| Unveiled by H2B2 Electrolysis Technologies, Inc. (H2B2), the solar PV hydrogen production plant in Central California, "SoHyCal," is the first and the largest green hydrogen plant in North America and began operations in November this year. |

The project envisages 100 percent clean hydrogen production using PEM technology, with a nameplate manufacturing capacity of up to 3 tons of green hydrogen per day using solar energy from a photovoltaic (PV) plant.

The hydrogen facility is expected to transition into its second phase with solar power sometime later in the second quarter of 2024. In its full capacity, the SoHyCal plant can support hydrogen well enough to power up to 210,000 cars or 30,000 city buses in a year.

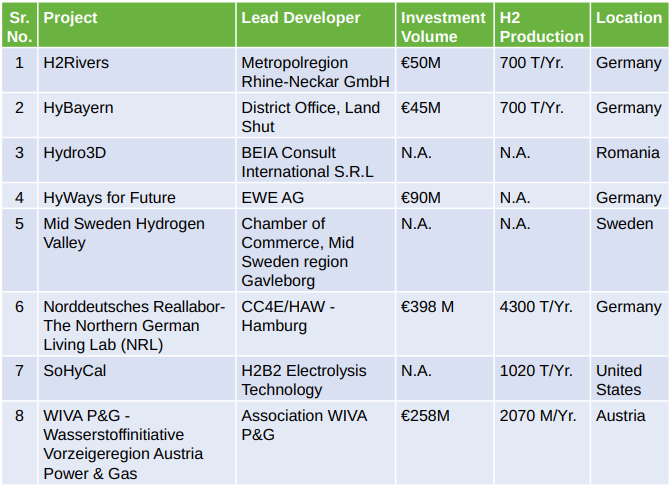

In addition to the operational hydrogen valleys, here's a list of under-construction projects: